redrive – SEG Automotive co-engineered by FERSA

When two strong partners come together and engineering know-how meets remanufacturing competence, redrive emerges – a concept for the remanufacturing of high-voltage electric drive modules like the drive unit for Tesla cars.

regain mobility – Remanufacturing of high-voltage electric drive modules

redrive – SEG Automotive, co-engineered by Fersa.

Each partner is an experienced automotive original equipment manufacturer and brings their ‘core’ competencies into the cooperation – this is not only literally visible in the name, but also in the product. Fersa provides the engineering expertise and SEG Automotive contributes its remanufacturing experience.

Via professional remanufacturing, we restore the physical function and mobility of high-voltage electric drive modules.

Both companies see remanufacturing as a contributor for a sustainable future.

Discover redrive – the remanufacturing innovation of high voltage electric drive units.

Follow the simple receive, replace, return process as the workshop receives the remanufactured drive unit and replaces the defective unit that is returned to SEG Automotive for the remanufacturing process.

recognize the partners

realize the benefits

redrive – the start of a journey together

Learn how the idea for redrive started and what both companies will bring in to realize this exciting new cooperation.

awareness – what was the starting point for the idea?

It all began in the US, when a Fersa employee discovered a backyard full of Teslas that were inoperable due to a malfunction in the electric drive unit. It turned out that the cause of the malfunction was a bearing failure – a clear opportunity for Fersa as a bearing manufacturer.

realization – how to make the idea happen?

There is obviously a market for repairing drive units. However, spare parts are scarce, have long lead times and are very expensive. In addition, there are already a significant number of cars on the road that are out of warranty period. So why not offer specific bearing repair kits to replace the faulty original bearings in the electric drive unit? When the repair kits were introduced to garages, the feedback from the mechanics was very positive. However, in addition to repairing the drive unit, they were also considering replacing the whole unit as it would be much easier and less expensive.

remanufacturing – but how?

The immediate solution was to remanufacture the entire drive unit. Lacking the experience and facilities, Fersa looked for a partner with knowledge in remanufacturing of rotating electrical machines. In SEG Automotive, with years of experience in industrial manufacturing as an OE supplier in the automotive business, they found the perfect partner. For SEG Automotive, the opportunity was obvious from the start, as they were looking for ways to expand their aftermarket business in terms of market coverage, product lines and remanufacturing. In addition, high voltage (HV) remanufacturing is a perfect complement to the existing Reman portfolio of starters, alternators and 48V starter-generators called Boost Recuperation Machines (BRM).

For both companies, working together was the final step in making this venture a reality.

agreement – how will the two companies work together?

Fersa and SEG Automotive have agreed to collaborate, leveraging the strengths of both companies to ensure a swift time-to-market. Both partners strive to be pioneers in this business and to be no. 1 in quality and speed to market. Fersa brings its in-depth knowledge and engineering expertise in bearing solutions. SEG Automotive receives the defective powertrain units at its facilities for the remanufacturing process. During this process, among other components, worn and defective bearings will be replaced with Fersa's reinforced versions. SEG Automotive is responsible for final testing and shipping.

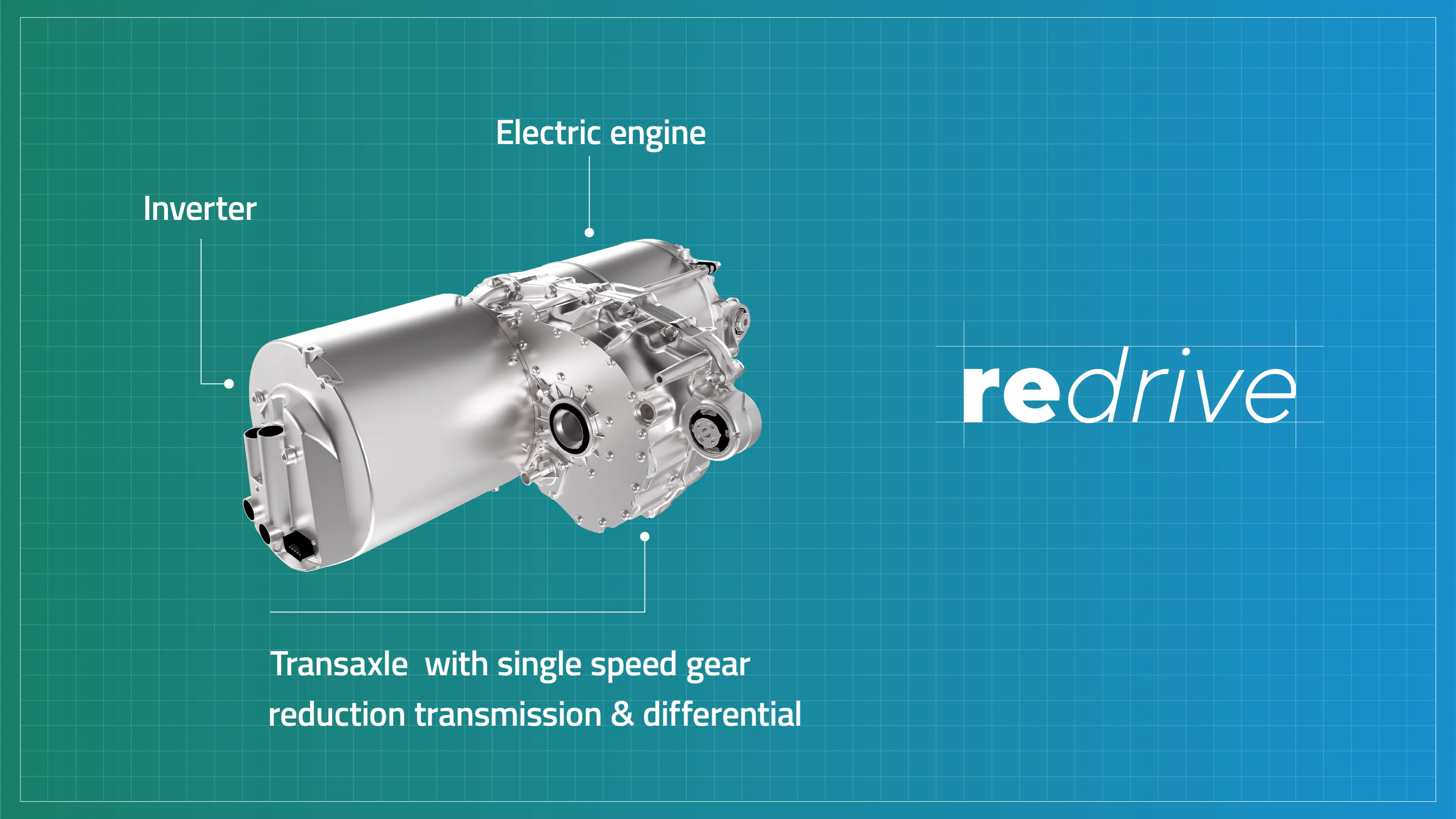

reveal the Electric Drive Unit

The drive unit is a critical component in electric vehicles (EVs). It combines the electric motor, gearbox, and power electronics into a single, compact unit.

Electric Motor:

The electric engine converts electrical energy from the battery into mechanical energy to drive the wheels.

Gearbox:

The gear box provides the necessary gear reduction to convert the high-speed rotation of the electric motor into a more suitable speed and torque for the wheels. Typically, electrical drive units feature a single-speed gearbox, as electric motors provide a wide torque range and don't require multiple gears like internal combustion engines.

Power Electronics:

Power electronics of an electric drive unit includes the inverter, which converts direct current (DC) from the battery into alternating current (AC) for the electric motor. It manages the power flow between the battery and the motor, controlling speed and torque output.

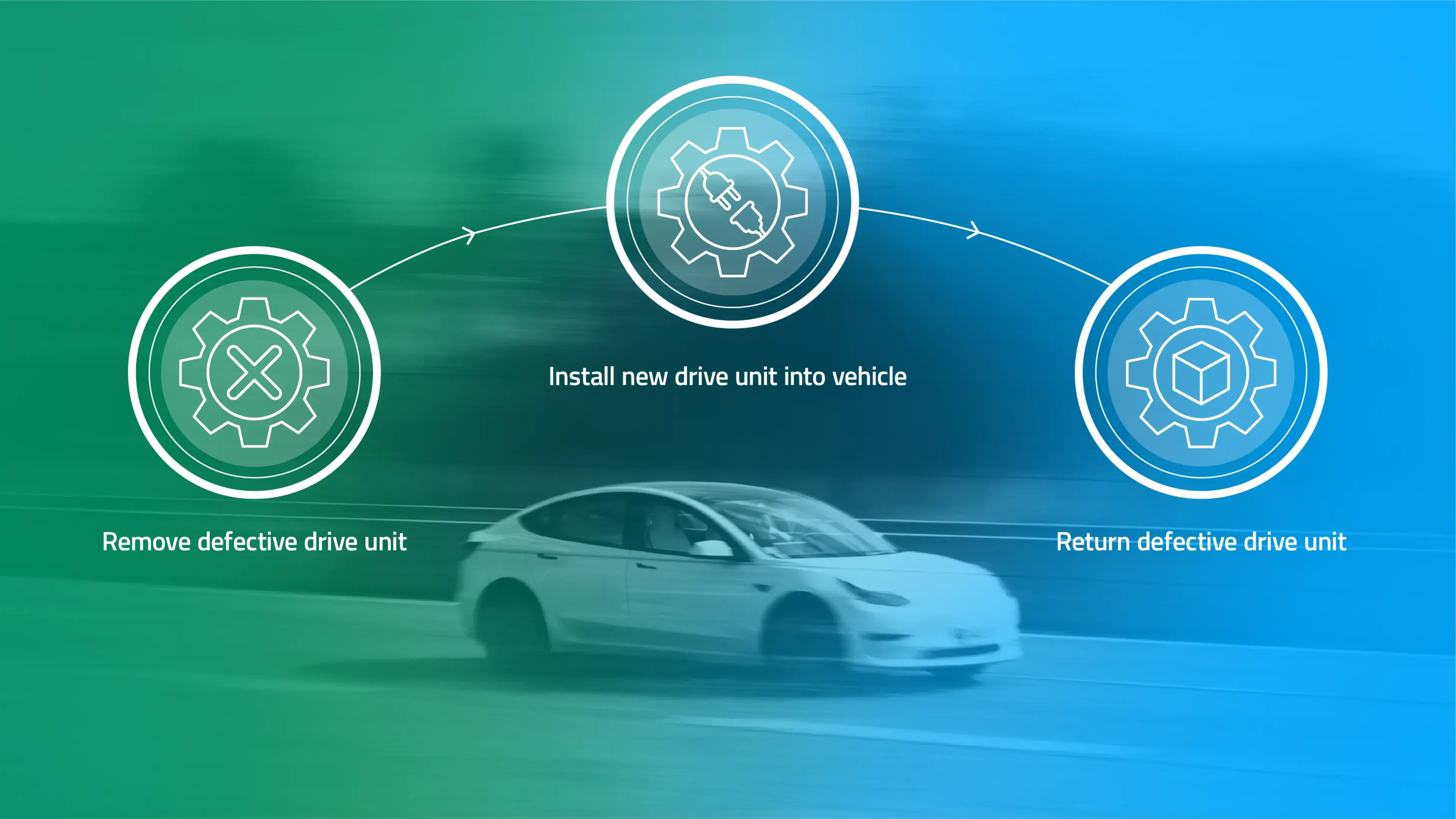

really as easy as can be

The redrive process explained in 3 simple steps.

- Once the remanufactured electrical drive unit arrives at the workshop, the faulty unit is removed from the vehicle.

- The remanufactured electric drive unit is installed and adapted to the car.

- The defective electrical drive unit is sent to SEG Automotive for remanufacturing.

respect the environment

Remanufacturing not only saves money by reusing most of the components in an electric drive unit, it is also beneficial to the environment.

By eliminating the need for energy-intensive resource extraction and component manufacturing, remanufactured drive units use much less energy and resources than new products. This makes a significant contribution to reducing CO2 emissions and conserving resources. For electric vehicles, which are designed to reduce the environmental impact of driving, remanufactured electric power trains are particularly suitable as they support this concept.

reach out to us

SEG Automotive Germany GmbH

Lotterbergstraße 30

70499 Stuttgart

Germany

Phone: +49 711 4009-8000

Mail: aftermarket.europe@seg-automotive.com

Fersa

Bari, 37

50197 Zaragoza

Spain

Phone: +34 690 131 466

Mail: ana.lecha@fersa.com