SEG Automotive Reman

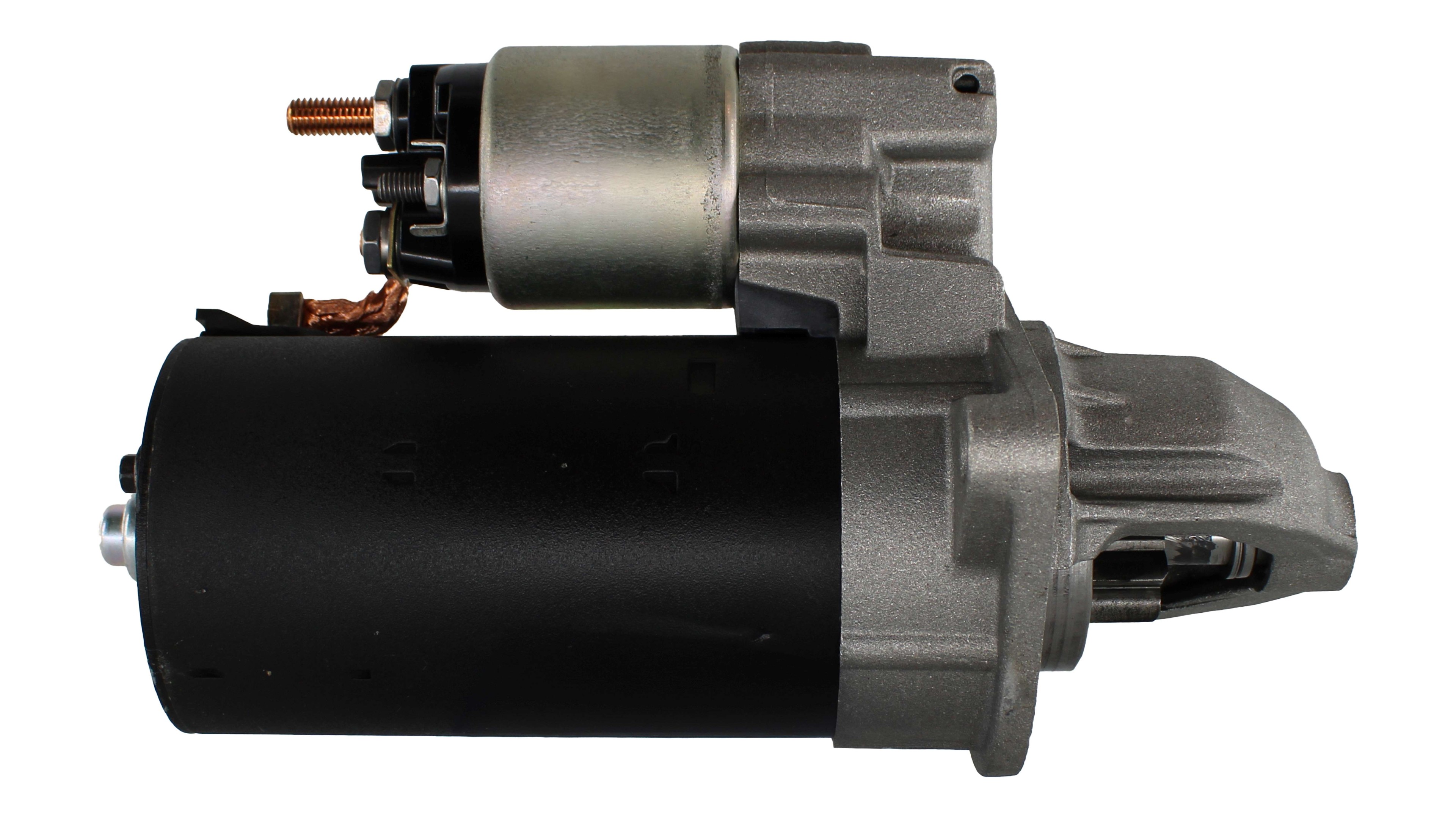

Our remanufacturing program is the circular economy in action. Remanufactured products from SEG Automotive meet the requirements for new products in terms of quality and service life. As part of our sustainability strategy, the remanufacturing program is an important contribution to conserving resources and reducing CO2 emissions.

Remanufacturing at SEG Automotive – Extended sustainability

At SEG Automotive we are dedicated to sustainability and social responsibility.

As a result, our products are inherently designed to reduce emissions. With our remanufacturing program we continue to enhance our contribution to a more sustainable future.

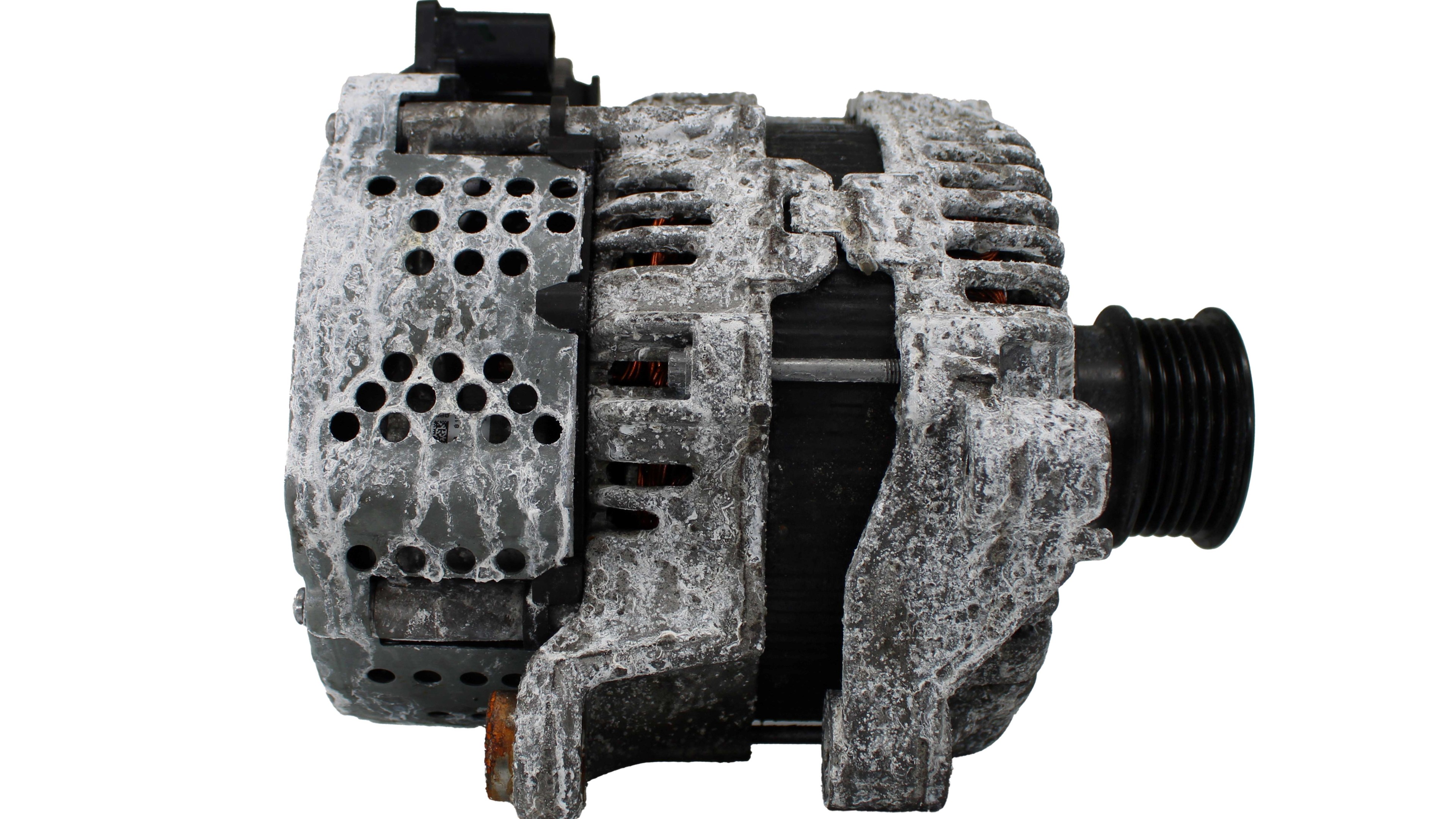

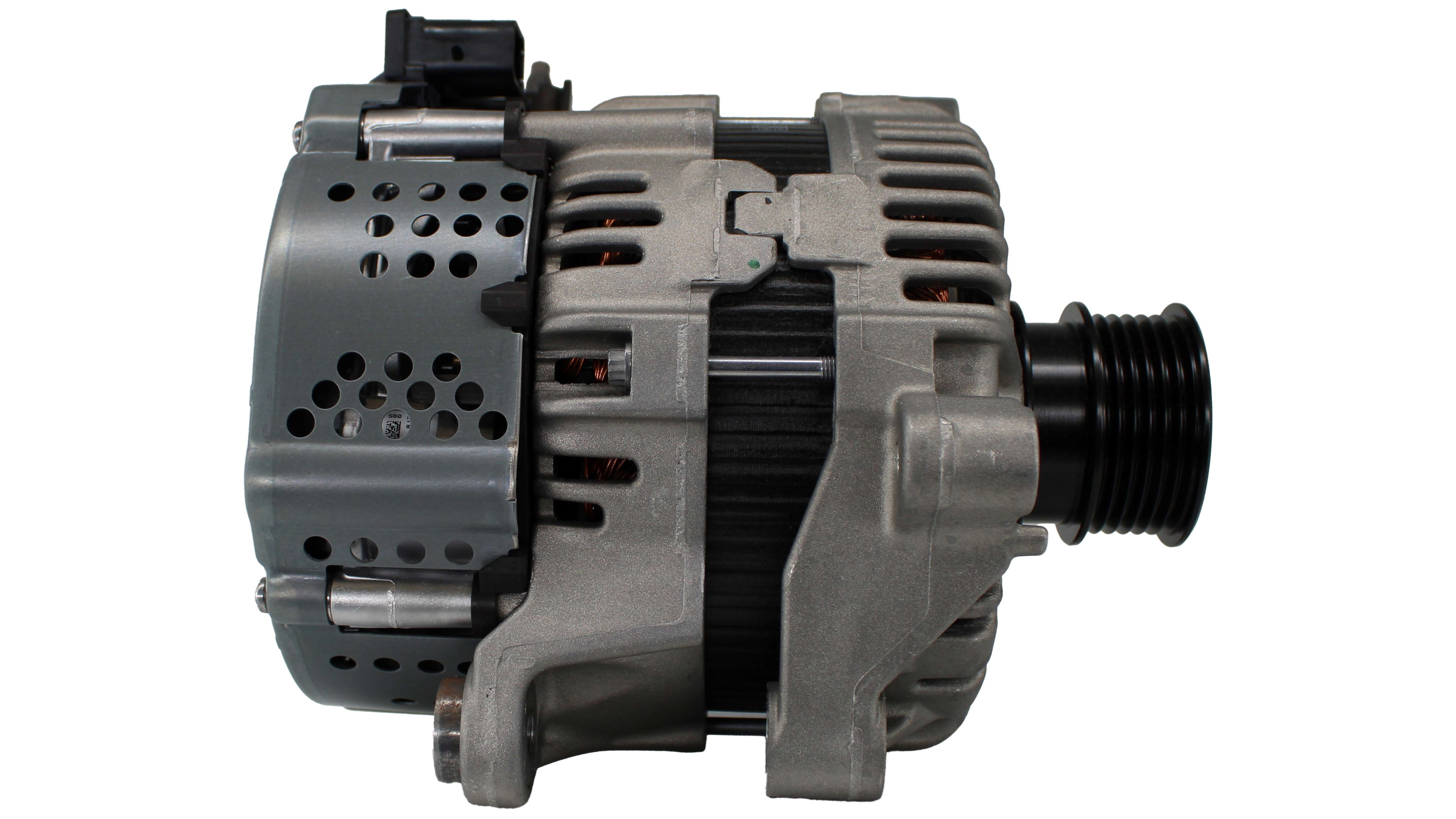

We restore used original SEG Automotive products back to their original performance and transfer them to a second life cycle – saving resources, reducing waste and minimizing our CO2 footprint. Combined with our OE manufacturing expertise we are able to offer cost optimized products without any compromises on quality, thereby extending a vehicle’s lifetime.

Because it

We wanted to know exactly.

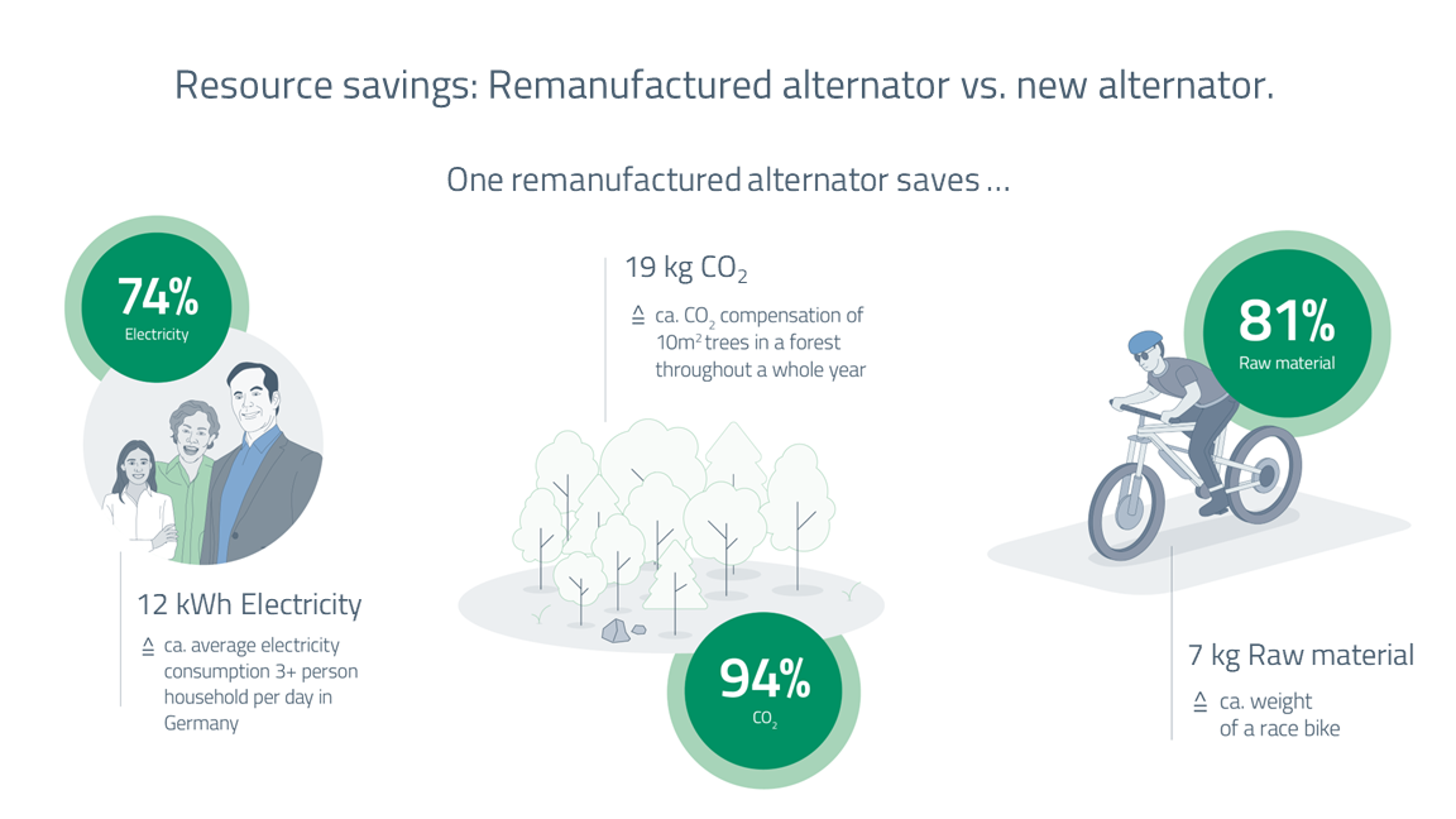

Therefore we analyzed the environmental impact of our Remanufacturing process in our Spanish production plant. The results speak for themselves. We are proud of our contribution to more environmental protection and a more sustainable resource utilization.

When comparing a new alternator* to a remanufactured alternator, we save 74 % electricity, 81 % of raw materials, and reduce CO2 emissions by 94 %.

[Opens in a new tab] Bundeswaldinventur 20217 / [Opens in a new tab] Bundeswaldinventur 2017 PDF / [Opens in a new tab] Statistisches Bundesamt - Stromverbrauch Private Haushalte Deutschland / [Opens in a new tab] Wikipedia - Rennrad

*Comparison based on alternators used in commercial vehicle applications.

From old to Reman in only 5 steps - circular economy in action

Follow the path of an extraordinary transformation.

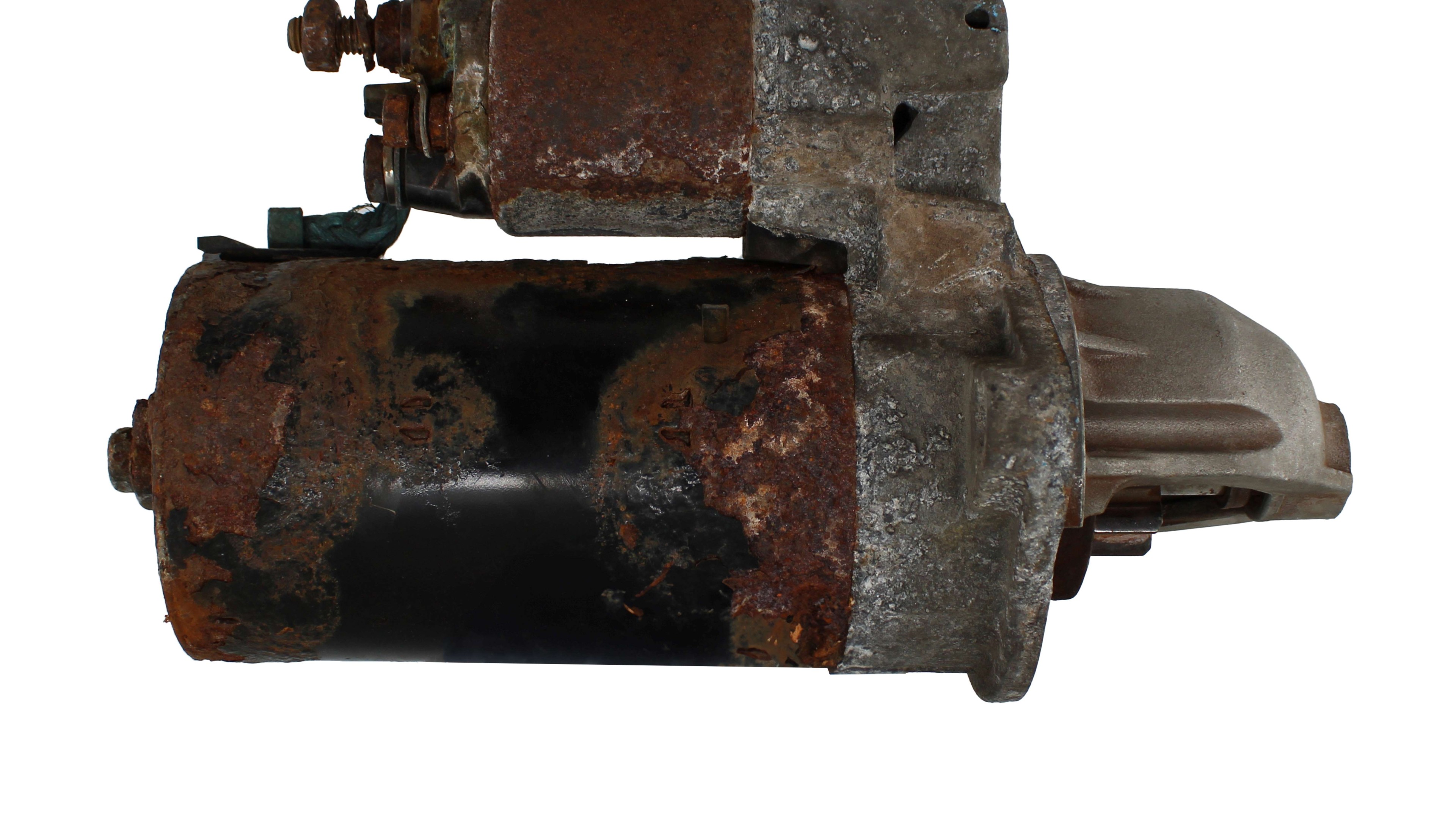

Send back home.

Upon arrival at the garage, the new remanufactured product replaces the worn or defect part in the vehicle. The alternator, starter motor, or Boost Recuperation Machine (BRM) that is removed, will be put back into the box and safely returned to one of our remanufacturing facilities.

We check for good.

As soon as our SEG Automotive products are returned from their first life operation, they are being identified, inspected and sorted according to the SEG Automotive return quality criteria. By that we ensure the quality of our remanufactured products at the very beginning.

Getting to the core.

All sorted products, commonly referred to as “core”, are disassembled into individual components. Non-reusable parts that do not fit the quality criteria are forwarded to the recycling process. All components that pass the review process are cleaned and prepared for the next remanufacturing steps.

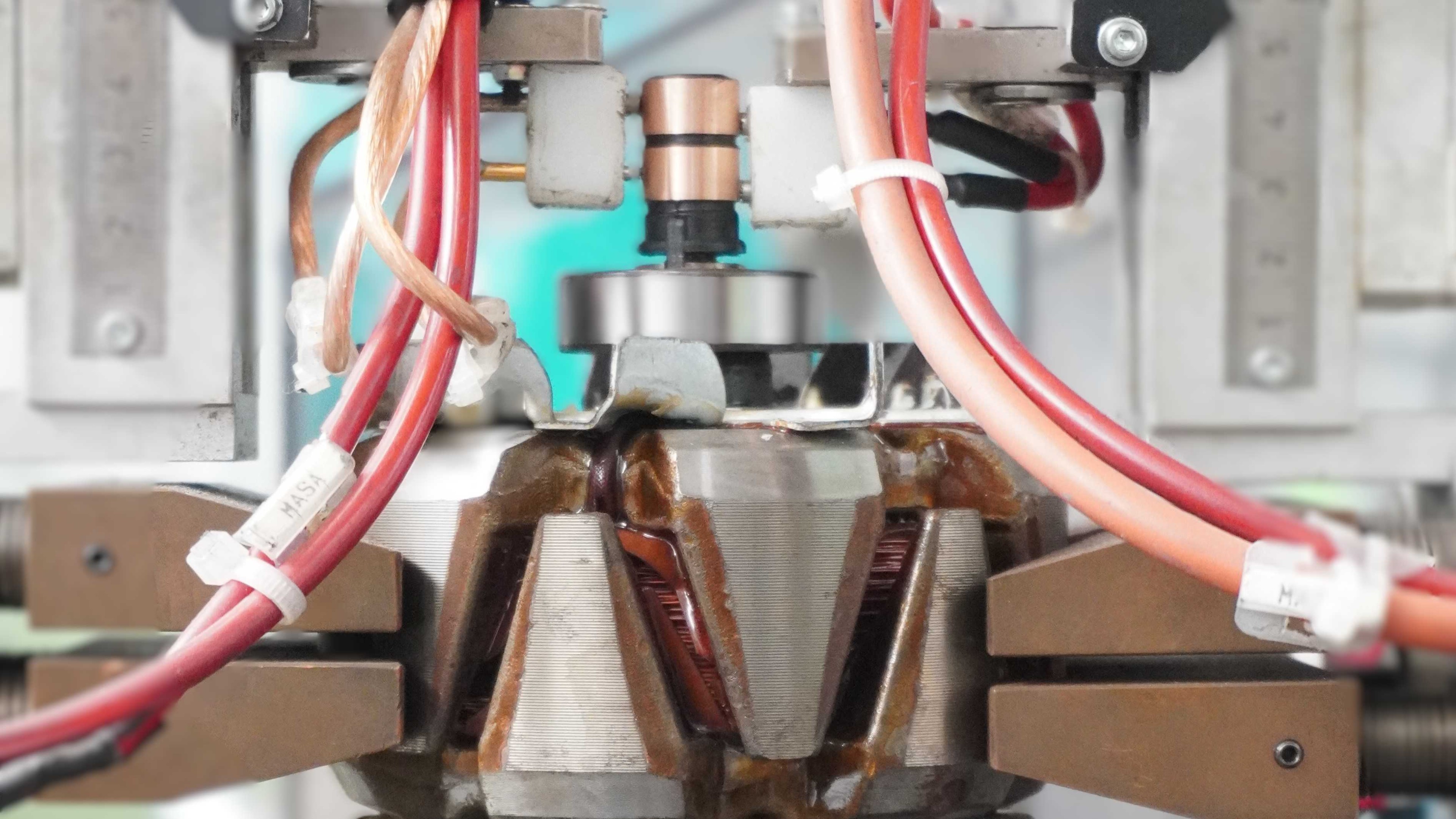

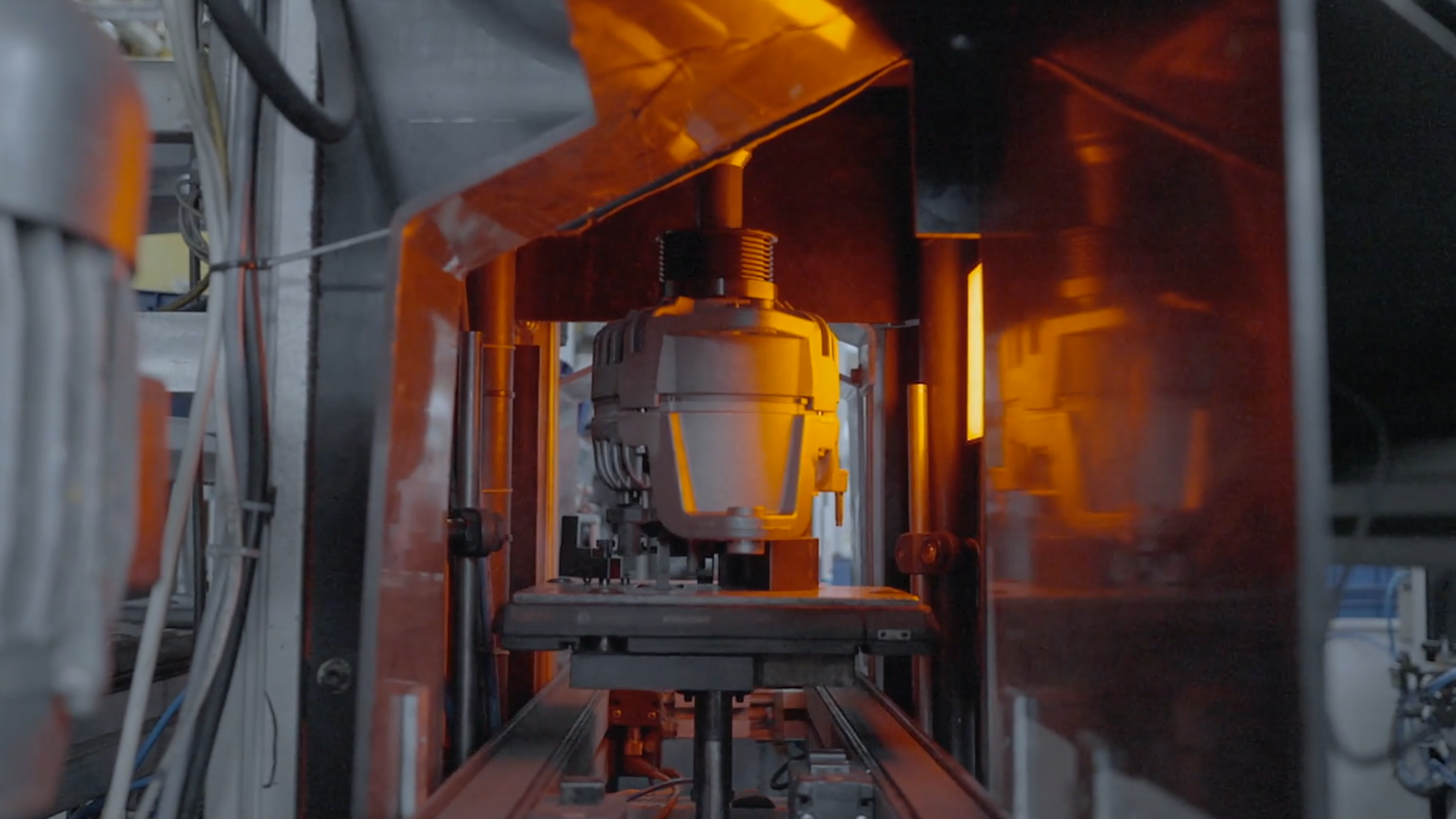

The art of Reman.

Based on our know-how as OE manufacturer we evaluate, measure and functionally check all individual components in automated supported processes. Consequently, the components are reconditioned or replaced with new ones in OE quality, followed by the preparations for the final assembly.

All good things come together.

The individual components are reassembled on our certified OE production lines. Subsequently, the remanufactured products undergo automated, strict 100 % quality end-of-line tests, with no distinction between a remanufactured item and a new product. This meticulous approach ensures that we maintain our high-quality standards. In the final step, all products are prepared for packaging and shipment to our customers. Of course, all our Reman products are listed on TecDoc.

Our Reman champions -

Alternator, Starter & 48 V Boost Recuperation Machine (BRM)

Starter

48V Boost Recuperation Machine (BRM)