One concept – multiple applications: high voltage e-machine and

Tailorable to any powertrain: Our scalable high voltage e-machine traction machine allows for fast customization of power and package dimensions to a wide range of electrification requirements.

Our portfolio ranges from 48V up to 800V e-machines for powering BEVs (Battery Electric Vehicles), to anything in between.

Thus, our electric motors can serve as a power unit for pure electric as well as for plug-in-hybrid vehicles. As a traction motor, the electric motor converts electrical energy into mechanical power and provides hybrid or purely electric propulsion. It transmits its torque directly to the transmission gear based on the application.

From power class and torque to the cooling concept: We can individually adjust many parameters to your specific requirements, while maintaining the same outstanding level of quality, reliability and economies of scale. This can include, for example, supplying subassemblies or single components rather than the entire e-machine.

Components

The stator and rotor form the core of the e-machine. Based on over 100 years of experience with e-machines, we can tailor these components to the specific needs of your application in terms of dimensions and output.

This means adapting parameters such as:

- Stator and Rotor diameter

- Cooling concept

- Voltage Level

- Power (peak and continous)

- Torque (peak and continous)

- Wire diameter

Despite these adjustments to your specific requirements, our robust manufacturing processes allow us to maintain the outstanding level of quality, reliability and economies of scale SEG Automotive is known for.

E-machines and components

-

High voltage traction e-machine

![]()

- Highest machine efficiency and power density enabling extended driving range

- E-machines classes for various powertrains up to 320kW

- Scalable output power, flexible speed-torque performance

- Optimized electromagnetic design for better Noise, Vibration, Harshness (NVH) performance

- Oil or water cooled

- Powerful design process in place creating customized e-machines

- Flexible production concept handles different types of e-machines

- Delivery scope includes entire e-machines, subassemblies and components

-

High voltage e-machines for light commercial vehicles

![]()

- For light electric commercial vehicles and other applications.

- 3 phase, highly efficient permanent magnet synchronous machine (PSM)

- Pull-in winding technology

- Liquid cooled concept, Motors & Controllers

- Drive control system with diagnostics, protection features & CAN

- Compact execution with optimised electromagnetic design

- Ingress protection, IP67

-

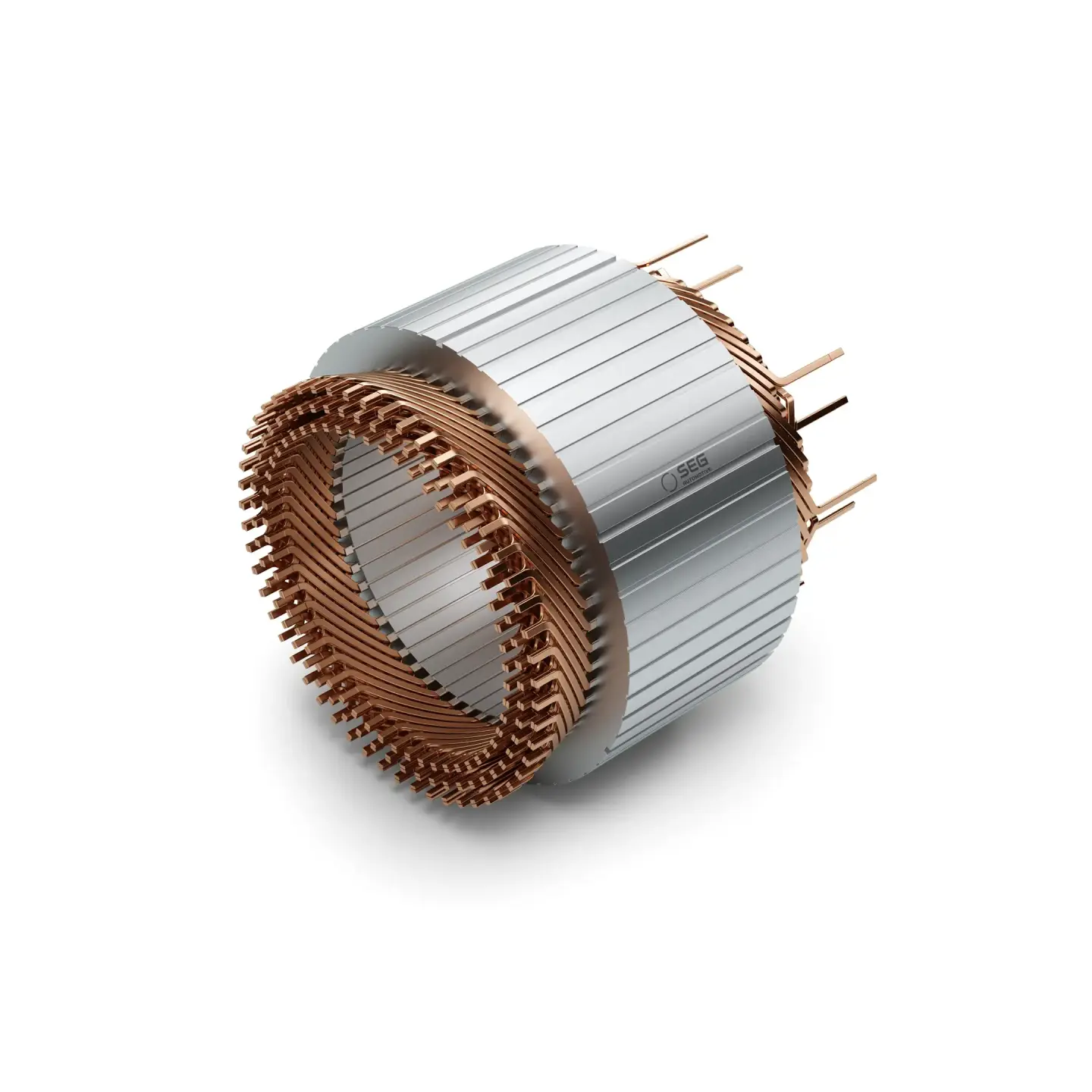

Stator

![]()

- Internal SEG Automotive Design (Build to Spec) as well Customer Designs (Build to Print)

- Support of Design to Cost and manufacturibility for customer designs (Co-Design work)

- Flexible stator and rotor diameter up to 270 mm and length up 180 mm

- Flexible production concept handles different types of e-machines and voltage classes

- Delivery scope from main sub-assemblies (rotor, Stator) to single components

-

Rotor

![]()

- Internal SEG Design (Build to Spec) as well Customer Designs (Build to Print)

- Support of Design to Cost and manufacturibility for customer designs (Co-Design work)

- Flexible stator and rotor diameter up to 270 mm and length up 180 mm

- Flexible production concept handles different types of e-machines and voltage classes

- Delivery scope from main sub-assemblies (rotor, Stator) to single components