A clean step into the future: New Inverter assembly line in Treto

SEG Automotive is rapidly driving forward its transformation from a pure hardware to a true mechatronics company: We have just inaugurated a new inverter line in Treto, Spain – enabling us to now not just develop a full e-drive system in-house, but also produce it in Europe.

We are known across the world for the reliability and quality of our hardware. However, as vehicle systems continue to become more complex by integrating advanced electronics and software, relying solely on hardware – and external suppliers for software and inverters – was not sustainable.

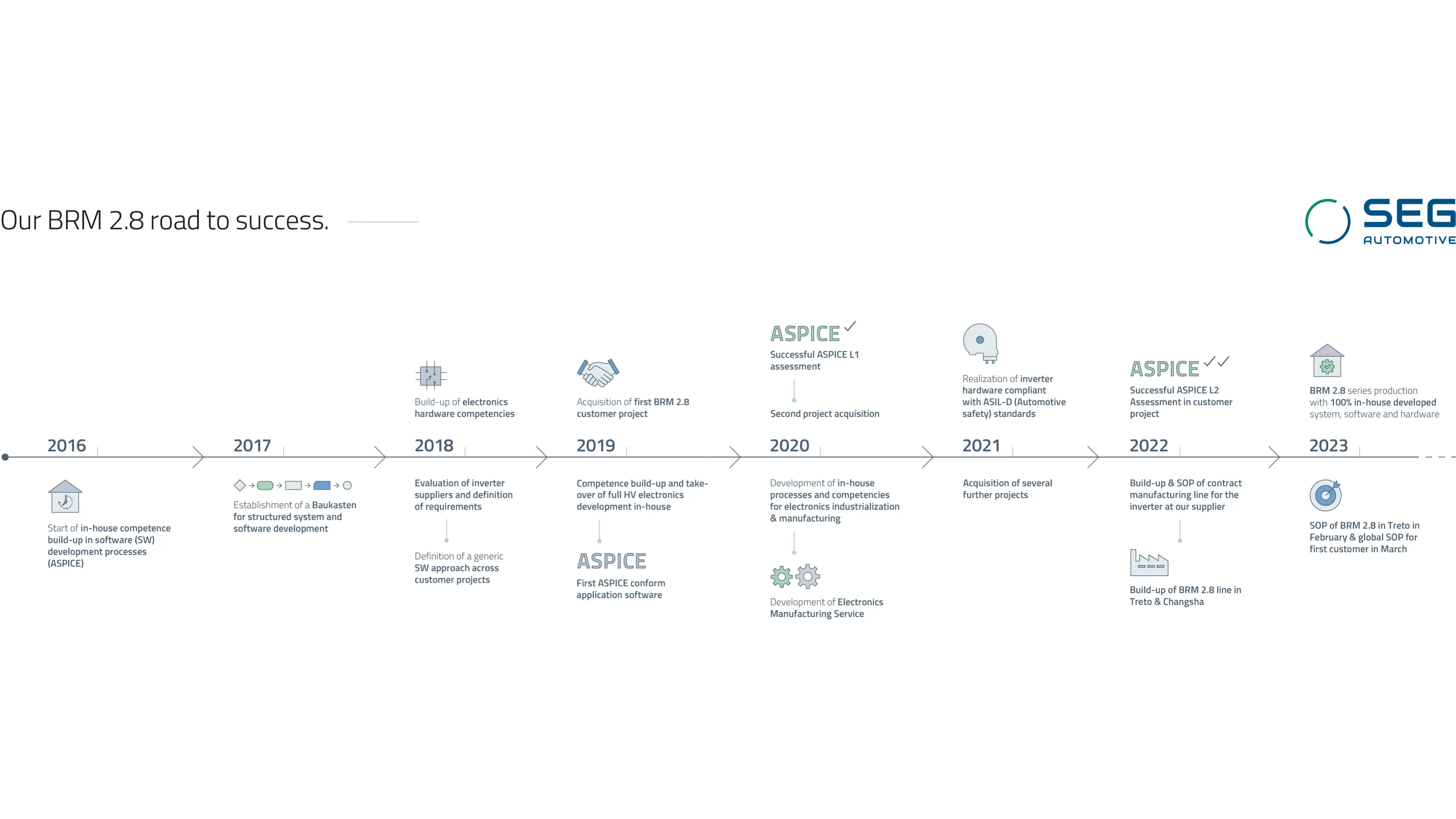

This was still the case when we launched the first generation of our 48V Boost Recuperation machine in 2017.

Since then, we have invested greatly in our unique people, building dedicated teams for software and electronics, and acquiring invaluable competencies—including achieving ASPICE Level II certification. Last year, when we brought the second generation of the BRM into series production, it marked our first fully in-house developed e-drive with software, electronics, and hardware all engineered by SEG Automotive.

Now, we took the next major step towards a strong mechatronics company by also bringing the inverter assembly in-house into our plant in Treto – celebrated in a high-spirited inauguration together with Spanish Minister of Industry and Tourism, Jordi Hereu and the government of Cantabria.

The Minister emphasized that SEG Automotive's new electronics area is "a fundamental piece for Europe," highlighting the future of electrified mobility and the significant shift toward hybridization of vehicles. During the ceremony, he encouraged the industrial sector to draw inspiration from what he called the "spirit of Treto."

SEG Automotive CEO Ferdinando added his perspective, stating that “the launch of our first inverter assembly line in Europe really shows how much this company and the skills of its unique people have developed. Our colleagues have shown incredible knowledge and commitment – and their work over the past nine months to set up the new electronics production area has been exemplary. Together, as #OneTeamOneCompany, we are building our future as the motor of mobility.”

The new dedicated electronics area features a 3,000 square meter 'clean room' and laboratory for the final assembly of the inverter. Logistically, this consolidation is ideal: E-machine production, inverter assembly, software engineering, and final assembly will all occur under the same roof, reducing transportation, warehousing costs, and risks.

This significant investment, totaling over 20 million euros, was generously supported by the Spanish government with a contribution of 9 million euros from the European 'Next Generation' funds.

The production capacities in Treto complement SEG Automotive’s already running high voltage e-machine and inverter manufacturing in Changsha, China. This enables SEG Automotive to maintain its role as a trusted global supplier to the world’s largest OEMs and emerging e-mobility players alike.

Press contact

SEG Automotive

Christoph Hoelzl

Press Officer / Pressesprecher

Tel.

[Opens in a new tab]

+49 711 4009 – 8172

[Opens in a new tab]

press@seg-automotive.com