SEG Automotive expands aftermarket portfolio with POWERbattery

SEG Automotive is known as a manufacturer and supplier of starter motors, alternators, 48V Boost Recuperation Machines (BRM) and spare parts components in the OE and aftermarket. Now the company also offers 12V batteries for cars, transporters and commercial vehicles under the name POWERbattery.

Why POWERbatteries from SEG Automotive?

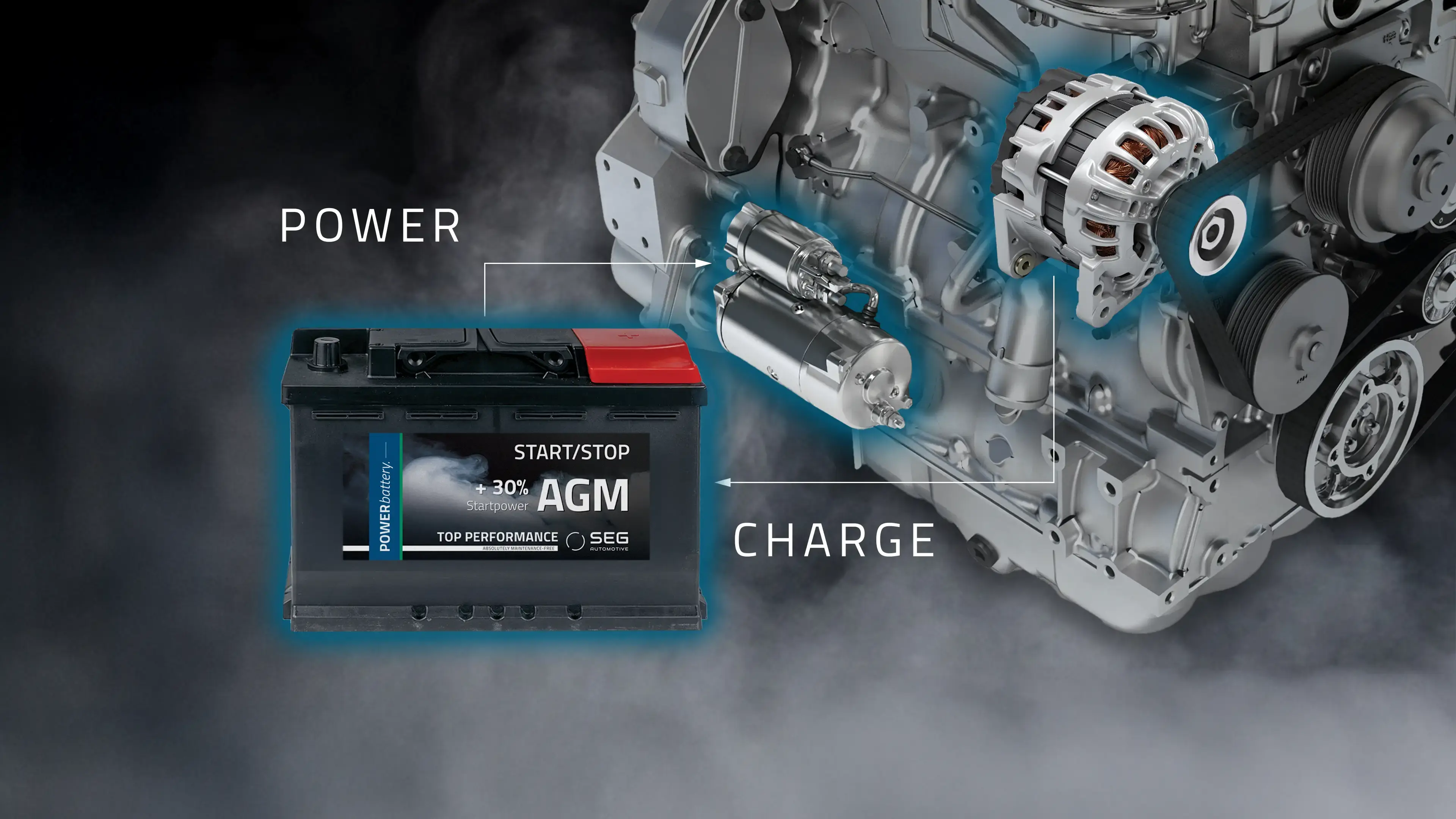

SEG Automotive, the expert in the field of rotating machinery, offers the ideal complement to its starter motors and alternators with the POWERbatteries.

A high-performance battery provides the energy that the conventional or start/stop starter motors need to get the engine moving. While driving, SEG Automotive's highly efficient alternators ensure that the battery is recharged.

In the aftermarket, the new 12V vehicle batteries from SEG Automotive not only stand for OE quality, maximum performance and reliability. Rather, it combines other decisive advantages for workshops and end customers:

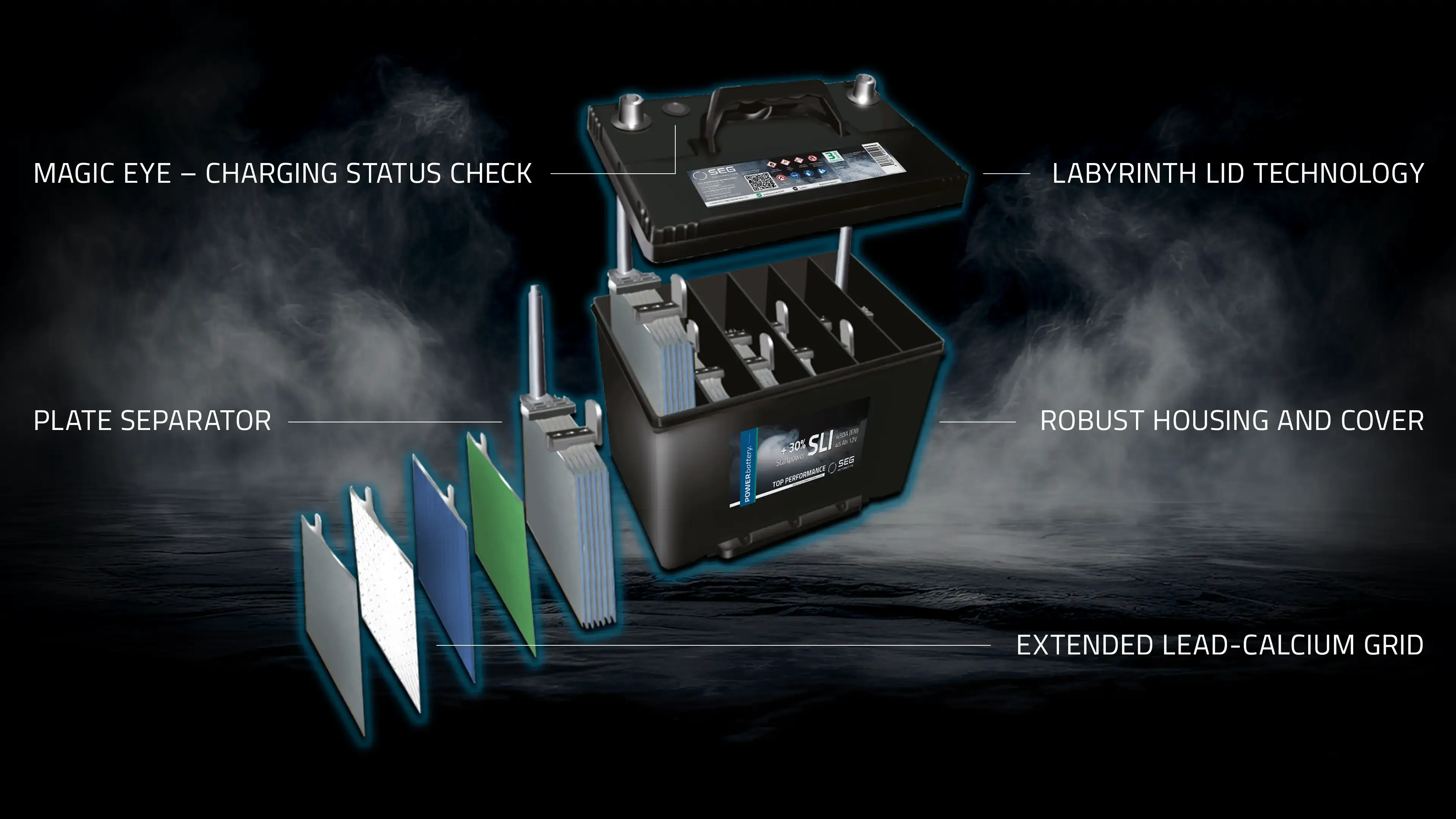

The integrated Magic Eye charge level indicator enables quick and uncomplicated control of the battery status – without the need for an additional measuring device.

Plate separators ensure maximum operational safety by ensuring efficient current flow, withstanding vibration and preventing short circuits between plates. Thanks to the innovative labyrinth lid technology, the battery is completely maintenance-free. Safety locks, flame arresters and a central degassing system offer reliable protection against leakage.

A robust housing and a reinforced lid ensure high mechanical resilience – ideal for demanding operating conditions. An advanced lead-calcium grid complements the overall concept and ensures particularly low self-discharge, even with longer service lives, as well as high corrosion and heat resistance.

The performance package is rounded off by a warranty of 3 years or 12 months from a capacity of 110 Ah.

There is a choice of three high-performance battery technologies: the classic lead-calcium battery (SLI), the long-lasting Enhanced Flooded Battery (EFB) and the particularly powerful Absorbent Glass Mat battery (AGM).

With only 9 item numbers, SEG Automotive already covers 97% of all passenger cars, with 3 item numbers 95% of vans and with another 5 item numbers 90% of commercial vehicles.

The batteries are suitable for all types of drive – from classic combustion engines (ICE) to mild and full hybrids (MHEV, HEV) to plug-in hybrids (PHEV) and all-electric vehicles (BEV).

The car battery in the workshop today

According to the ADAC ( [Opens in a new tab] ADAC Roadside Assistance Balance 2024) failure or discharge of the starter battery is the most common cause of vehicle breakdowns. Therefore, regular checks and timely replacement in the workshop are of central importance.

In workshops, the handling of car batteries today is much more safety-conscious than in the past. The modern batteries from SEG Automotive are completely sealed, leak-proof, tilt-proof and absolutely maintenance-free. This means that no more water needs to be refilled, as there is no significant degassing. This eliminates the need to work with open lead-acid batteries, so protective gloves and goggles are not required when handling car batteries.

Good after-sales vehicle service always includes checking the battery's state of charge. With POWERbatteries from SEG Automotive, the state of charge can be checked quickly and easily by the driver himself at any time – thanks to the so-called Magic Eye. This integrated indicator on the battery allows an immediate assessment of whether the charge level is sufficient or whether it should be recharged – without the need for an additional measuring device.

If the battery needs to be recharged, modern chargers automatically detect the connected battery type and control the charging process accordingly – adapted to AGM, EFB or classic lead-acid batteries.

In case the battery needs to be replaced, it is advisable to replace it professionally in the workshop. It is important to correctly connect the new battery to the vehicle using a workshop test device. The so-called BEM code (Battery Energy Management) ensures that all comfort functions – such as the time, stored radio stations or seat positions – are immediately available again after the replacement.

If a battery change is not possible in the workshop, many vehicles with an open battery management system automatically detect the new battery after some time. As a rule, all comfort functions are fully available again after a few hours.

Tasks of 12V car batteries in modern vehicles

The main task of the battery in the combustion engine is to provide electrical energy to activate the starter motor and start the engine. After starting, the battery continues to power the spark plugs in gasoline engines to maintain the combustion process. In diesel engines, this function is omitted during driving because the diesel fuel does not require spark plugs due to its compression-ignition properties. However, the glow plug installed in diesel engines also requires electricity from the vehicle battery to start the engine.

The battery in vehicles with start/stop systems is put under heavy strain because the engine has to be restarted frequently. As a rule, particularly powerful batteries, such as the EFB and AGM batteries from SEG Automotive, are used for this purpose.

In addition, however, there are now up to 100 electrical consumers that have to be supplied with energy while driving. These include vehicle lighting, a variety of control units, sensors, driver assistance systems, onboard infotainment systems and external multimedia devices such as tablets and smartphones. AI-supported voice assistants with permanent online access are also being used more and more frequently.

A classic 12-volt battery will also continue to be used in hybrid and electric vehicles. When the vehicle is at a standstill, it supplies the basic systems in standby mode and, as in vehicles with combustion engines, feeds the entire 12-volt on-board electrical system as well as all connected consumers. Depending on the vehicle architecture, the 12V battery is recharged from the high-voltage battery via a voltage converter in electric vehicles or via the generator of the hybrid combustion engine in hybrid vehicles.

Car Battery Technology

A car battery, usually in the form of a lead-acid battery, consists of cells connected in series that together deliver a voltage of 12.78 volts. There are two electrodes in each cell: a positive one made of lead dioxide and a negative one made of lead. These are embedded in an electrolyte of dilute sulfuric acid, which serves as a conductive medium. There are separators between the electrodes that prevent direct contact but allow ion exchange. The whole thing is housed in a robust, acid-resistant plastic housing that protects the battery from external influences. The battery is connected to the vehicle's electrical system via two connection terminals – positive and negative terminals. When discharging, the battery converts chemical energy into electrical energy, while when charging, this process takes place in reverse.

The development of the vehicle battery

The 1st generation consisted of classic antimony-lead (PbSb) batteries, also known as lead-acid batteries. They were characterized by high weight, strong self-discharge and high water consumption, which significantly limited their shelf life. The high water consumption resulted from gassing during charging, in which water breaks down into hydrogen and oxygen and evaporates.

With the 2nd generation, so-called hybrid batteries came onto the market, which used a combination of antimony-lead and lead-calcium (PbSb/Ca). Although these improved the shelf life and reduced self-discharge, they even had disadvantages compared to pure antimony-lead batteries in terms of charging behavior and cycle stability.

The 3rd generation brought significant progress with the introduction of lead-calcium batteries (PbCa). These batteries were around 5% lighter, offered three times longer storage time and about 30% longer service life compared to previous models. Due to these advantages, they have largely replaced the classic antimony-lead batteries. However, they also have some disadvantages, such as a charging voltage that is about 1 volt higher, lower cycle stability and increased acid stratification, in which the sulfuric acid settles at the bottom of the battery and leads to uneven concentrations in the electrolyte.

The 4th generation includes modern AGM batteries (Absorbent Glass Mat) or lead-fleece batteries and EFB batteries (Enhanced Flooded Battery), as also offered by SEG Automotive. AGM batteries differ from conventional lead-acid batteries in that all the acid is bound in a special glass fleece. Although this leads to a higher weight, it makes the battery absolutely leak-proof and significantly increases its performance. EFB batteries, on the other hand, have positively charged plates that are coated with a fleece. The special design ensures a significantly extended service life.

The biggest advantage of both types of batteries is their significantly higher cycle stability – about three to four times as much as lead-calcium batteries. This makes them particularly suitable for vehicles with start/stop systems – the AGM battery is also ideal for vehicles with recuperation technology (recovery of braking energy). In addition, both offer higher performance for the increased energy requirements of modern vehicles and significantly improved behavior during deep discharge.

For more information, please visit [Opens in a new tab] our dedicated page..

Press contact

SEG Automotive

Christoph Hoelzl

Press Officer / Pressesprecher

Tel.

[Opens in a new tab]

+49 711 4009 – 8172

[Opens in a new tab]

press@seg-automotive.com