Happy Birthday, dear starter motor!

111 years production and development at SEG Automotive.

111 Years starter motor at SEG Automotive

We are celebrating the 111th birthday of the starter motor at SEG Automotive and can therefore also look back on over a century of automotive history.

The first cars still had to be started manually with a crank, which was not only exhausting but also dangerous and often led to injuries. The invention of the electric starter brought significantly more comfort and safety.

From the early days of the automobile, when cars were more reminiscent of carriages, to the present day, when cars are described as moving smartphones, a lot has changed in other respects too. But no matter how the car has evolved, SEG Automotive still produces the right starter motors for all types of vehicles, such as small cars, trucks, buses and agricultural and construction machinery, as an original equipment manufacturer.

This also benefits the aftermarket: we manufacture SEG Automotive aftermarket parts on the same production lines as the series products and therefore offer the same OE quality in the aftermarket.

Celebrate 111 years of starter production at SEG Automotive with us. Follow all activities over the next two weeks on our online and social media channels!

Overview.

Quality since 1914: For us, not just a trend, but tradition.The evolution of the starter motor – Over a century of technological progress.

Strong from the inside – the components of the starter motor explained.

Invest in quality: Our starter motors are the smart choice.

From city cars to heavy-duty trucks – PC and CV starter motors compared.

In small as well in large - Original spare parts from SEG Automotive.

Sustainability and quality – a perfect match for remanufactured starter motors.

Essential in operation and in emergency situations – starter motors in commercial vehicles and special applications worldwide.

Quality since 1914: For us not only a trend, but tradition

SEG Automotive celebrates 111 years of starter production. As one of the leading OE manufacturers, we have been developing and producing innovative starters for more than a century.

What once began with the idea of replacing the tiresome hand-cranked engine start with a convenient and reliable solution has developed into a global success story. Today, our starters are used in millions of vehicles on every continent – from small cars to commercial vehicles.

Continuous research, close cooperation with our partners and the commitment of our employees are key components of this path.

Rethinking the engine start – the history of the starter motor at SEG Automotive.

The story begins in 1914 with the development of the electric starter motor under the company name Bosch at the time. Since then, the German term “Anlasser” has become commonplace in German garages to this day. However, the more appropriate and internationally recognized term is “starter motor”. Ultimately, however, both terms mean the same thing.

Initially, starter motors were slow to spread as they depended on powerful batteries, which were still being developed in the early years of the automobile. By the 1930s, sales had risen to over 500,000 units produced in-house, but it would take until the 1950s for the hand crank to be completely replaced by the electric starter motor, which was used in millions of vehicles.

In the early 1950s, the principle of the pre-engaged-drive starter motor became widespread and formed the basis for all subsequent developments until the 1980s. A further milestone was set with the introduction of permanent magnets and planetary gears. These innovations made it possible to continuously reduce the weight and dimensions of the starter and thus gradually increase the efficiency of the vehicles.

The last significant technological leap came in 2007 with the introduction of the start-stop starter. This made it possible to switch off the engine when stopped at traffic lights or in traffic jams and restart it immediately when driving on. This innovation led to considerable fuel savings and a reduction in CO₂ emissions in road traffic.

We provide an insight into the technical development in our overview of the evolution of the starter.

Demand is growing – new locations emerge.

As the demand for starter motors grew worldwide, so did the need for new production and sales locations for SEG Automotive. The first branches were established in the USA in 1913, followed by market entries in Brazil (1954), India (1989) and China (2004). Starters were produced for the European market at the Spanish plant from 1978 to 2009, with a total of more than 27 million units manufactured there. Since its opening in 2003, the Hungarian plant had produced 50 million starters by 2016. Today, that number has surpassed 90 million. The facility continues to supply high-quality starters for both the European original equipment market and the aftermarket.

Research and development – from idea to innovation.

Over the decades, the starter has undergone continuous further development – it has become more compact, lighter and at the same time more powerful and durable. The focus of these technical optimizations was on challenging operating conditions, such as extreme temperatures or high humidity.

In addition to the pure increase in performance, comfort also played a central role: noise development and vibrations were specifically reduced in order to make the starting process noticeably more pleasant and to significantly increase driving comfort.

This continuous improvement is the result of decades of research and development by an experienced OE manufacturer that combines technical innovation with practicality.

Environment and sustainability – responsibility requires change.

The innovations from development are also reflected in terms of sustainability. For example, more compact and lighter starters mean less material is used and fewer resources are consumed during production.

But that's not all: every gram less weight in the vehicle directly reduces fuel consumption – and therefore also CO₂ emissions in daily operation. Every weight-optimizing technical improvement therefore makes a significant contribution to reducing emissions.

Once the starter motors have reached the end of their life cycle, remanufacturing is the next logical step.Since 2021, starter motors have been given a second life at our plant in Hungary – using significantly less energy and materials than new production. This saves even more resources and significantly minimizes the carbon footprint.

For us, sustainability is not a trend, but a promise and every innovation is a step towards a more responsible future.

Looking ahead – the future of the starter motor at SEG Automotive

Even if electromobility is gaining in importance worldwide and vehicles with hybrid-electric or all-electric drives are becoming increasingly popular, the starter motor remains an indispensable component of modern mobility.

We are proud of our many years of expertise in starter motor technology. With passion and a spirit of innovation, we develop and produce starter motors that are used worldwide – reliable, powerful and future-oriented.

As long as starters are needed, we will be ready: with technical excellence, global delivery capability and the determination to provide our customers with the best possible support, even in a changing market.

The evolution of the starter motor – Over a century of technological progress

The development of the starter motor was continuous – but certain milestones were groundbreaking and had a decisive influence on further progress.

1914: Sliding-armature starter motor

The sliding-armature starter motor was the first starter motor based on the so-called Rushmore principle: The entire armature (also known as the rotor), i.e. the rotating part of the starter electric motor including the shaft, moves in the housing to push the pinion (starter gear) onto the ring gear of the motor flywheel. After this engagement, the full starter current is switched on. A spring mechanism ensures that the pinion and armature are returned as soon as the engine has started. The sliding-armature starter motor was operated via a foot switch in the vehicle. The switch was later integrated into the starter motor. The driver can easily start the vehicle using a starter button on the dashboard, which is connected to the starter switch.

1927: Inertia-drive starter motor

A new engagement technology was introduced with the inertia-drive starter motor. When activated, the pinion engages helically, which improves engagement with the engine flywheel. The full starter current is applied immediately.

1937: Sliding-gear starter motor

The sliding-gear starter motor introduced a further engagement mechanism. The pinion is now moved onto the engine flywheel by an engagement solenoid via an engagement lever. The full starter current is only activated once the pinion has engaged. A freewheel has also been installed to prevent the starter motor from over-revving as soon as the flywheel speed exceeds that of the starter motor.

1947: Pre-engaged-drive starter motor

The pre-engaged-drive starter motor combined the functions of its two predecessors and thus became the model for all modern starters. The solenoid activates the pinion via the engagement lever, which engages the engine flywheel via the steep thread on the armature shaft by means of a simultaneous screwing movement. The full starter current is only switched when the starter motor is successfully engaged. Overspeeding of the starter motor is prevented by a freewheel.

1982: Reduction-gear starter motor

In 1982, permanent magnets were installed in the starter motor for the first time, which led to improvements in compactness, weight and efficiency. The introduction of reduction gears in the form of planetary gears made it possible to increase the torque of the electric motor to drive the engine flywheel, while the torque required for starting remained unchanged. This further reduced the size and weight of the starter motor.

2007: Start/Stop starter motor

The first starter motor with a start/stop function went into series production in 2007. Its significantly increased number of possible starting cycles makes it possible for the engine to switch off at every stop at a crossing and in stop-and-go traffic and then be restarted to continue the journey. This leads to considerable fuel and CO2 savings, as the engine is no longer permanently in operation.

2025: Continous improvement & the next big leap.

Since its introduction, the start/stop principle has been continuously refined and the starting processes have become quieter and faster, further increasing comfort.

With the introduction of starter-generators such as the 48V BRM from SEG Automotive, the functions of the starter motor and the alternator are combined in one compact machine using intelligent electronics and enhanced with new functions such as braking energy recovery

From the mechanical beginnings to intelligent system integration – the development of the starter motor is still paving the way for efficient and sustainable mobility today.

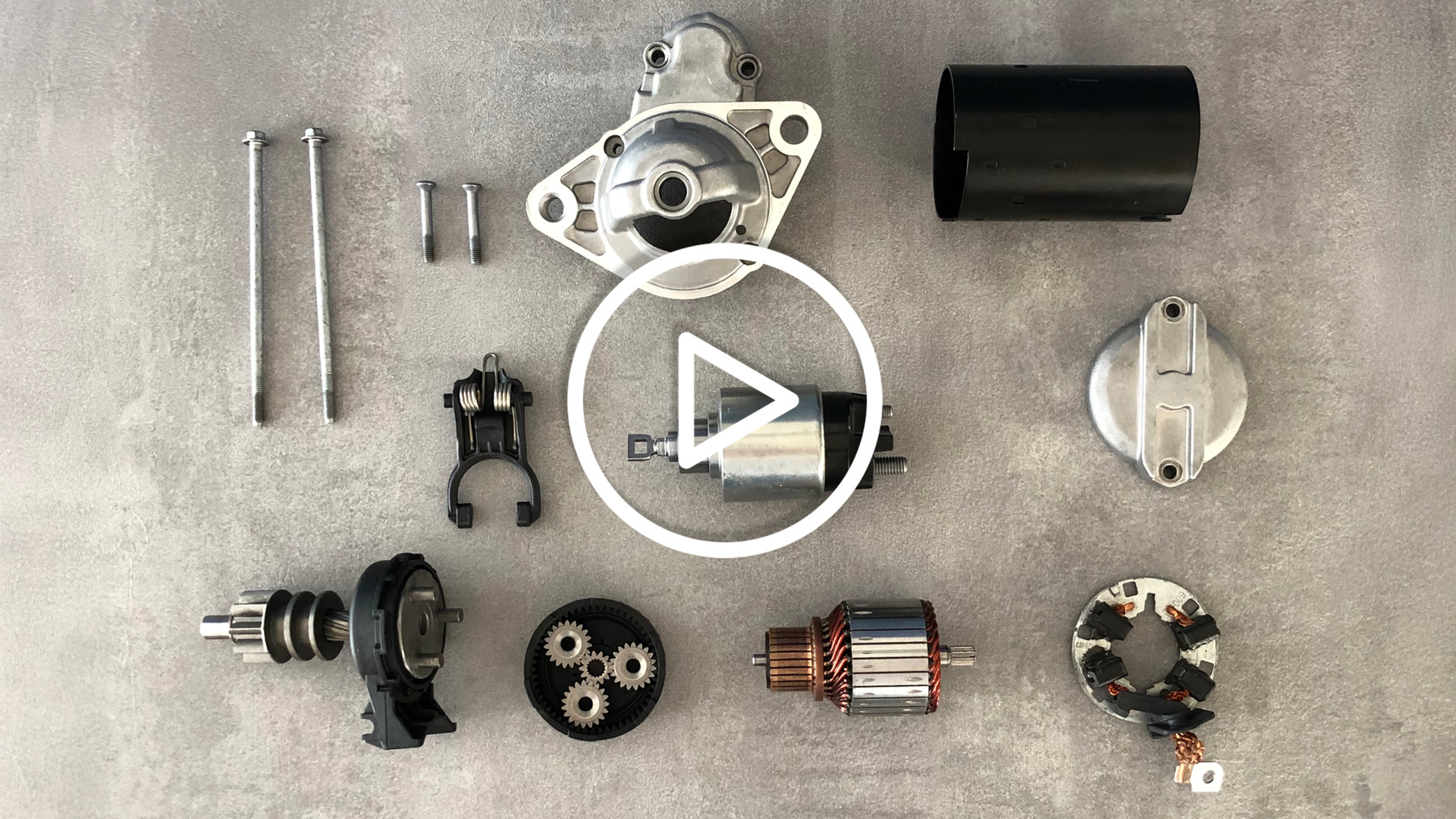

Strong from the inside – the components of the starter motor explained

A starter motor is essential for conventional combustion engines, as it is what sets the engine in motion in the first place. Without it, the engine would not be able to start on its own.

The starter motor has the task of bringing the engine up to a certain minimum speed, which is necessary for ignition to take place in the cylinders and the combustion process to start. To do this, it must overcome the engine's moment of inertia and set it in rotation.

This process requires the interaction of several components in the starter motor.

As soon as the ignition is activated, current flows through the solenoid coil, creating a magnetic field. This pulls the plunger into the solenoid, which in turn sets the engagement lever in motion.

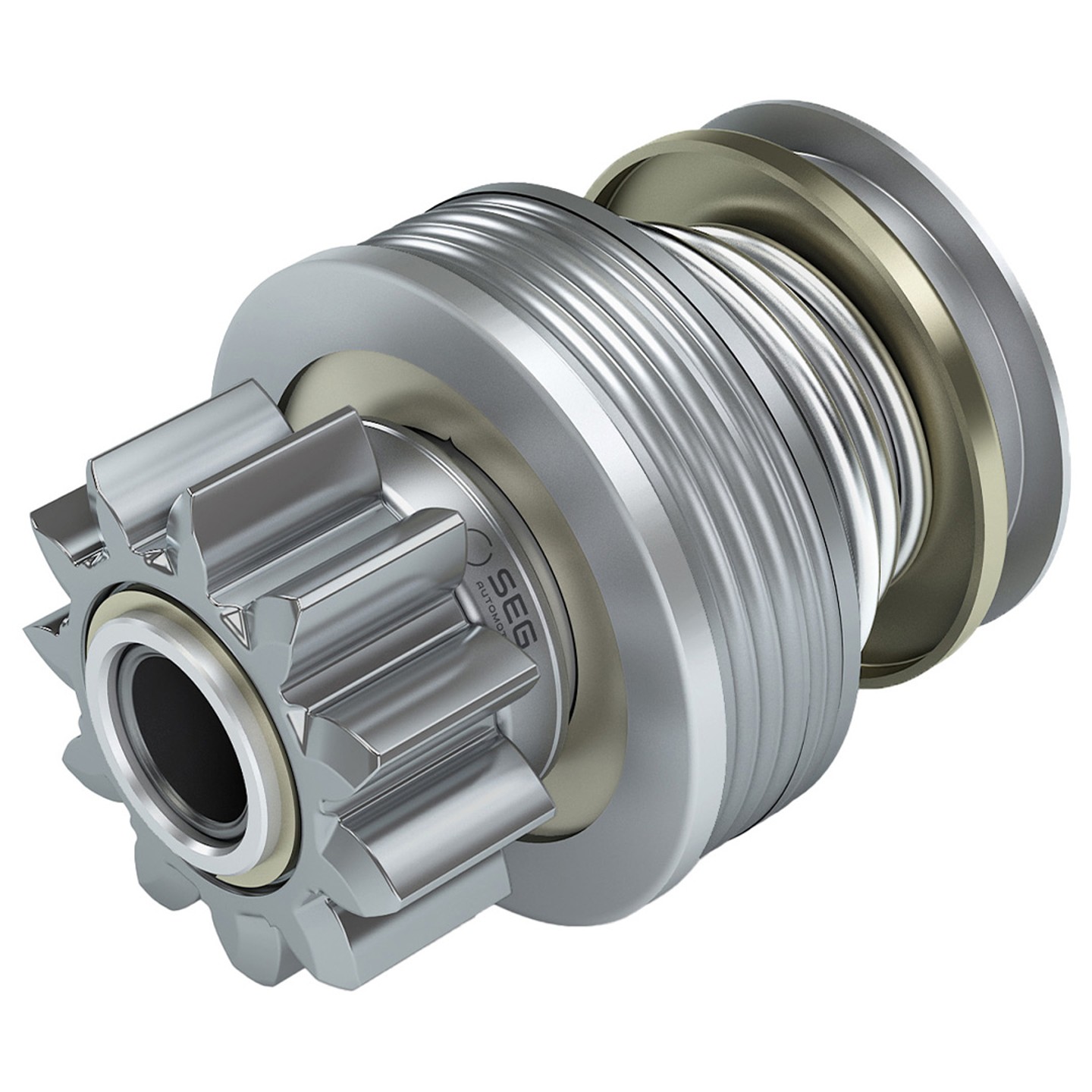

The lever pushes a small gear wheel, the so-called pinion, into the engine flywheel via a coaxial screw.

If the pinion is correctly engaged, another circuit is closed, causing the starter armature to start rotating.

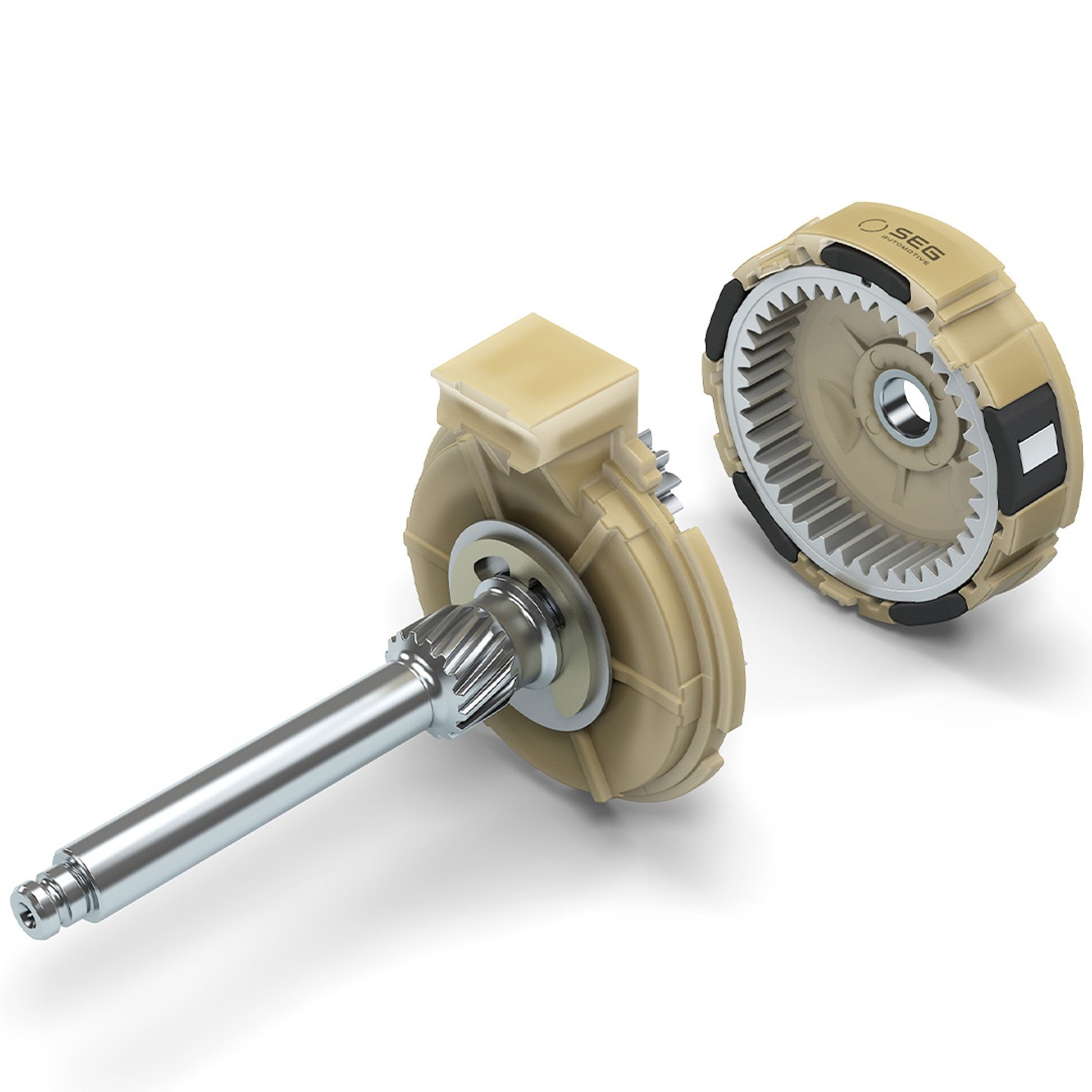

A planetary gear provides power reinforcement and efficiently transmits the rotary motion to the pinion. This drives the engine flywheel, which ultimately enables the engine to start.

The precise interaction of the components ensures a fast and reliable starting process.

A quick working and reliable starter motor requires less power. This reduces the load on the battery and protects the electronics. At the same time, mechanical wear is reduced, which puts less strain on the engine and other components. An efficient starter motor that is not overloaded also has a longer lifetime and needs to be replaced less frequently.

Invest in quality: Our starter motors are the smart choice

From city cars to heavy-duty trucks – PC and CV starter motors compared

As an essential component of a combustion engine, starter motors can be found in both passenger cars and commercial vehicles. Although they are identical in their basic function, there are some key differences due to the different requirements and operating conditions.

PC starter motors are generally smaller and lighter, as they only have to start motors with a lower output. The typical output is between 1.2 and 2kW. Commercial vehicles such as trucks or buses have larger and more powerful engines that require more torque to start. Their starters are therefore much more robust and powerful – often with outputs of 10 to 25kW.

Another difference lies in the operating voltage. Passenger cars are equipped with a 12-volt starter motor as standard. Commercial vehicles often use 24-volt systems in order to provide the higher power efficiently and reduce current levels.

The high demands on robustness and performance are also reflected in the weight of the commercial vehicle starter motor. The weight ranges from 7 to 16kg. Car starter motors are significantly lighter. Their typical weight is 2-4kg.

One particularly interesting aspect is the so-called power-to-weight ratio – i.e. the ratio of power to mass, typically expressed in kilowatts per kilogram (kW/kg).

Despite some considerable differences in size and weight between car and commercial vehicle starter motors, this ratio is almost identical for both. This means that both types of starter motors work with similar efficiency in relation to their mass.

This fact speaks for an optimized selection of materials, a well-thought-out design and a precise layout of the components – each adapted to the specific requirements of the respective vehicle.

In small as well in large - Original spare parts from SEG Automotive

The outstanding OE quality that we realize in our starter motors is also reflected in the starter spare parts. Each individual component is manufactured with the highest precision and precisely matched to the overall system. This ensures that all parts fit together perfectly and function reliably.

Starter motor spare parts from SEG Automotive are the ideal solution for repairing the starter motor in a timely and cost-effective manner.

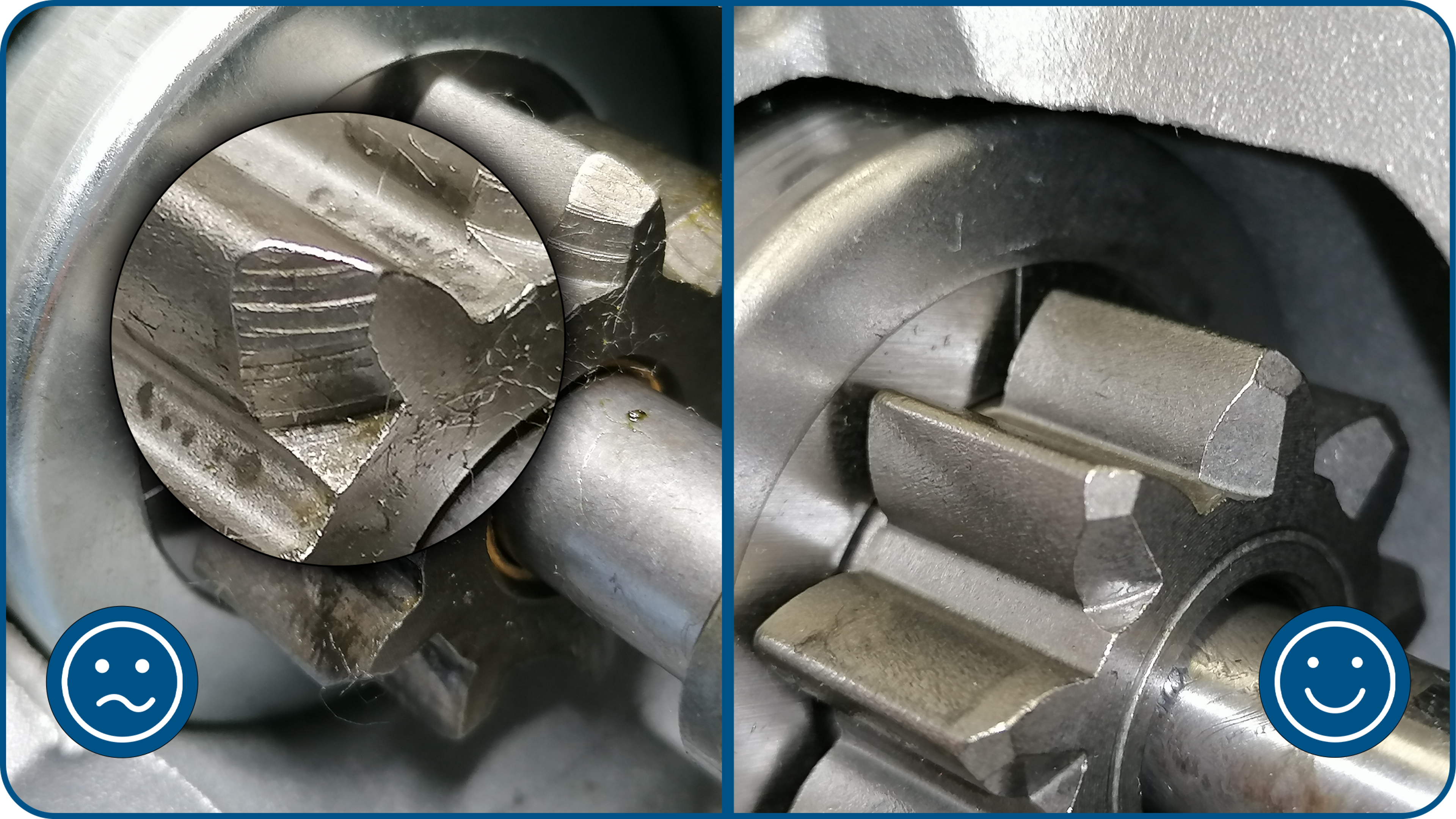

Pinions.

Precise manufacturing of the pinions ensures accurate meshing, which shortens the engine starting time. Precise fabrication and optimal pinion geometry ensure perfect tooth engagement, which minimizes friction losses and makes power transmission more efficient. This reduces wear on the components involved and increases the service life of the drive system.

Solenoids.

To prevent the ingress of dirt and moisture, magnetic switches are completely sealed – for permanently durable switching even under demanding conditions. The magnetic switches remain sealed even under severe temperature fluctuations and vibrations. This not only increases functional reliability, but also significantly extends the service life of the switches.

Engagement levers.

Our engagement levers impress with their lightweight yet robust design and enable precise movement of the pinion. They offer an excellent balance between weight and stability. Even under extreme mechanical stress, they are characterized by high structural strength and consistently reliable operation.

Planetary gears.

The precisely meshing gears of the planetary gear transmit the forces efficiently to the pinion – they are highly resilient for optimum torque transmission. The even load distribution over several planetary gears not only maximizes power transmission, but also significantly increases the lifetime of the gearbox. The compact design enables a high power density in a small package.

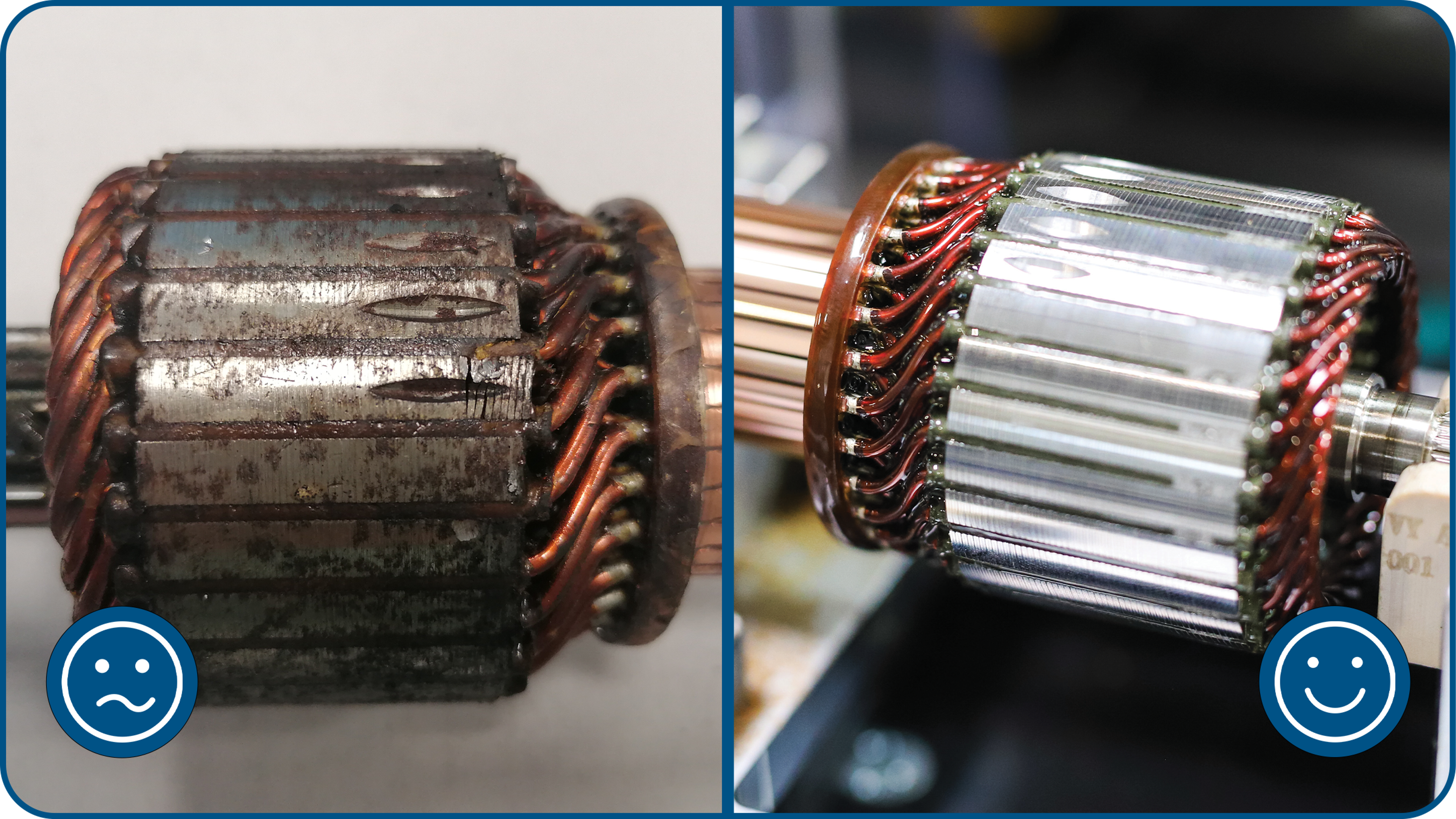

Armatures.

The armatures from our starter motor spare parts portfolio impress with their carefully manufactured rotor packs and high-quality windings. They ensure maximum efficiency in the starter electric motor and deliver consistently high performance. The insulating materials used are also particularly temperature-resistant, which minimizes the risk of short circuits. Due to their design, our armatures are extremely low-vibration and therefore contribute to the smooth running and durability of the entire starter motor.

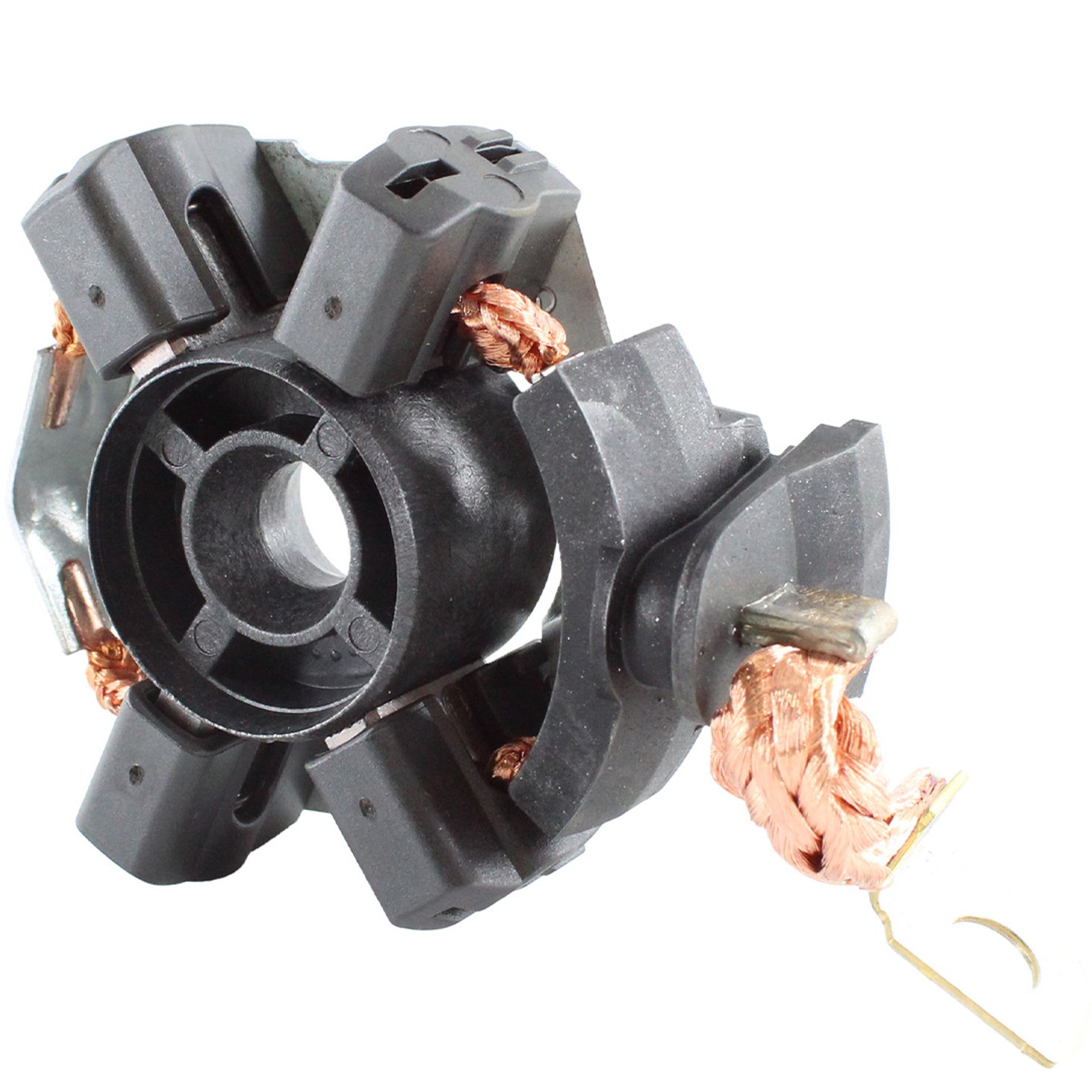

Carbon brush holders.

Carbon brush holders impress with their low-wear design, which ensures an even and stable current flow. The precise guidance of the carbon brushes reduces contact resistance, ensures even wear and thus minimizes the risk of sparking. This extends the lifespan of the entire system. The spring systems used ensure a constant contact pressure, which reliably maintains electrical conductivity even under vibrations and dynamic loads.

All our starter spare parts are designed for an optimum weight ratio. The result: maximum performance with minimum use of materials – in line with modern, efficient and resource-saving repair solutions.

Sustainability and quality – a perfect match for remanufactured starter motors

After countless starts, extreme conditions and years of stress, their work is far from over: our starters return – not to the shelf, but to the circulation system. In SEG Automotive's remanufacturing program, they are carefully checked, professionally reconditioned and repaired with original parts. This gives them a second life – ready for many more uses under the toughest conditions.

Remanufacturing at SEG Automotive is the circular economy in action: every returned starter motor is first identified, checked and broken down into its individual parts. Components that no longer meet the quality requirements are recycled, while reusable parts are thoroughly cleaned, measured and prepared for reuse. Supported by automated series production processes and OE expertise, the result is a Reman product that is equivalent to a new part in terms of quality and service life.

Not only is the program technically impressive, it also makes an active contribution to environmental protection. Remanufacturing conserves resources, reduces emissions and extends the service life of vehicles – without compromising on quality and reliability. Because even after 111 years of development experience, our claim remains the same: durable, high-performance and responsibly produced products for OE market and the aftermarket.