48V mild hybrids: What should be considered when replacing a belt-driven starter generator?

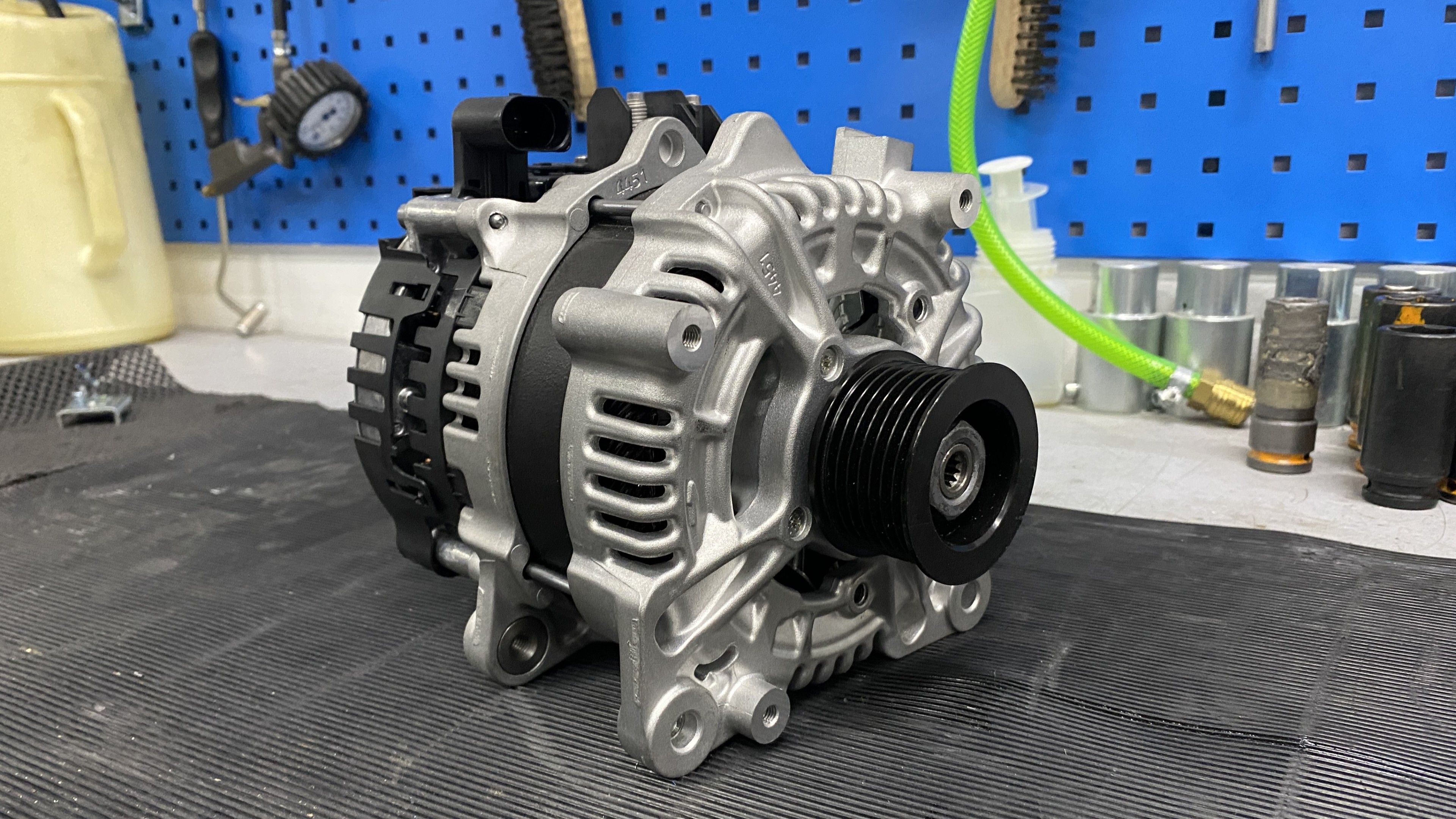

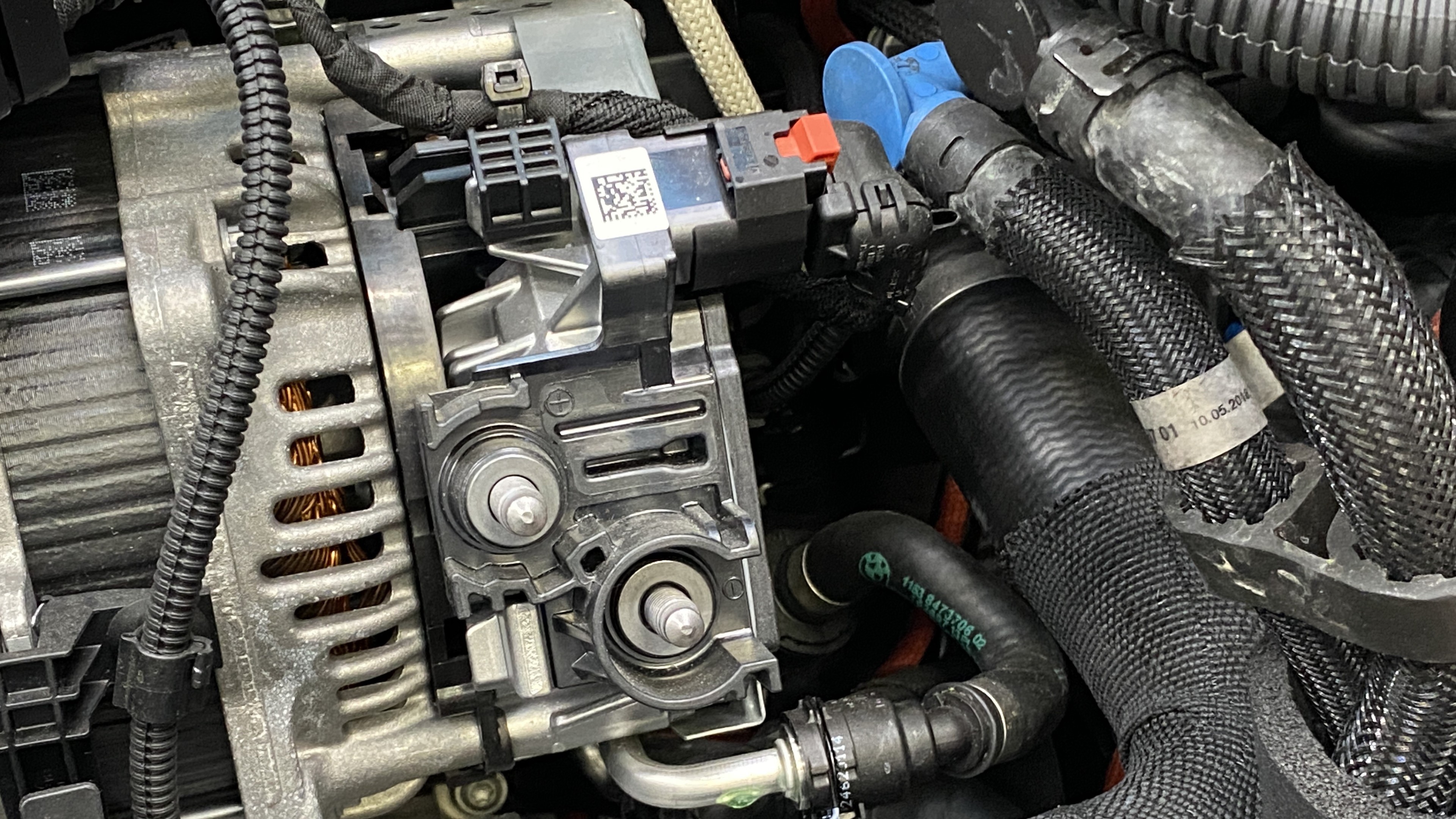

48V mild hybrids are on the rise, leading to a higher number of vehicles on the road—and therefore also in repair shops. BRM, RSG, BSG—there are many names for the belt-driven starter generator. For repair shops, replacing these compact fuel-savers is comparable to replacing an alternator.

What is the difference between a conventional alternator and, for example, a 48V “Boost Recuperation Machine (BRM)” from SEG Automotive?

The name says it all: BRM is introducing an additional 48V electrical system, enabling, among other things, the storage of braking energy in a 48V battery (recuperation). This energy is available as additional power when needed, e.g., for overtaking maneuvers (boosting). In addition, the 48V motor ensures a quiet, comfortable start and also offers active coasting (switching off the engine at constant speed, maintaining speed with battery support). All these measures reduce fuel consumption and CO2 emissions by 15%. The reason for this is the addition of an inverter to the classic alternator, which controls the additional functions.

How does the replacement work?

If there are problems with the 48-volt system, the engine warning light usually comes on first. Depending on the vehicle manufacturer, error codes such as “48V supply error, do not start” or “drive system maintenance required” may also be displayed. These codes, which are determined during vehicle diagnostics, can be either universal or manufacturer-specific.

They can be used to narrow down the cause of the fault pattern by process of elimination. In addition to the 48V battery, this could be the BRM electronics or the machine itself. If it is defective, it can also be replaced by independent workshops. Due to the <60V contact voltage, additional high-voltage training, certifications, or a special high-voltage workstation are not required.

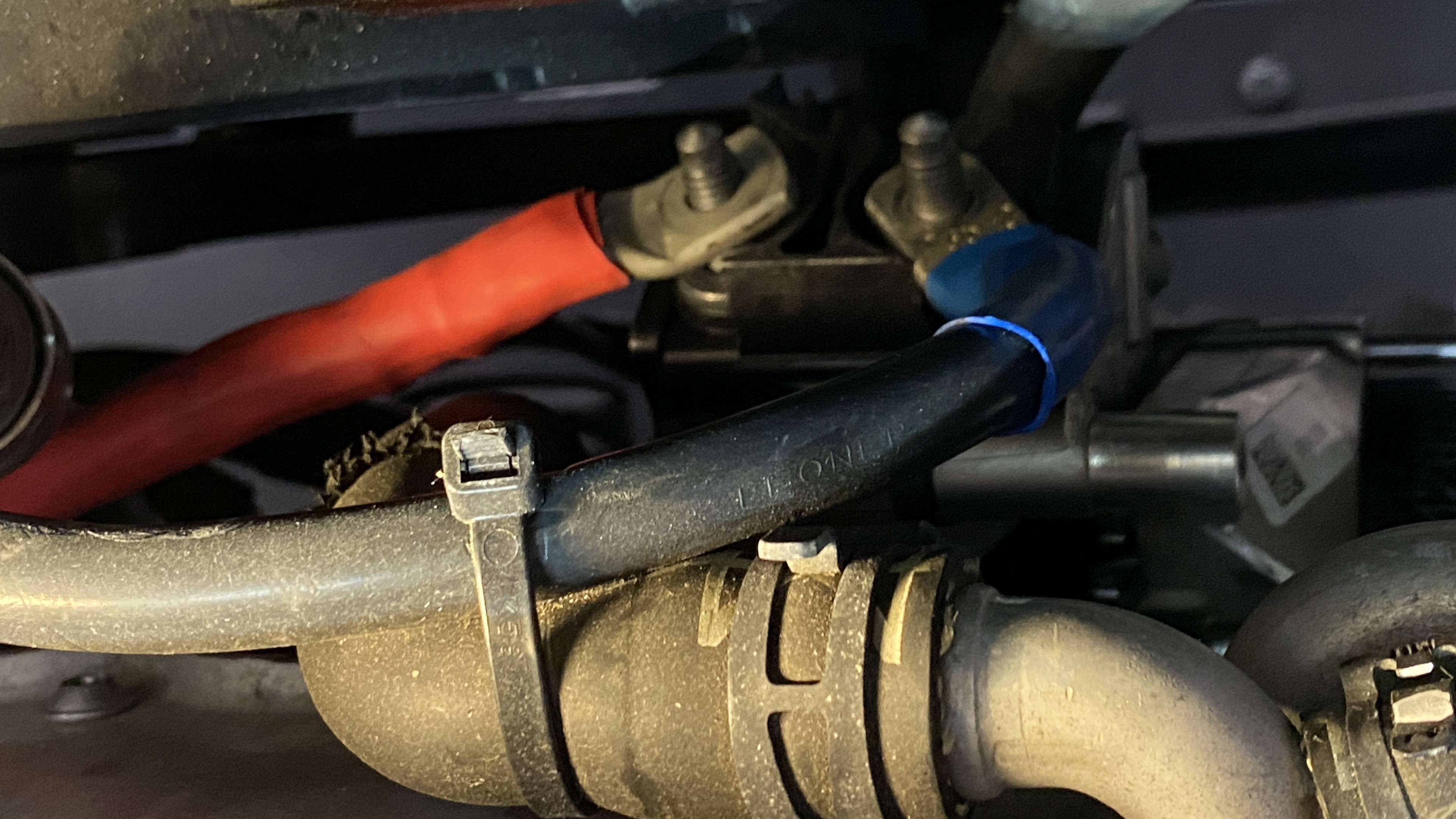

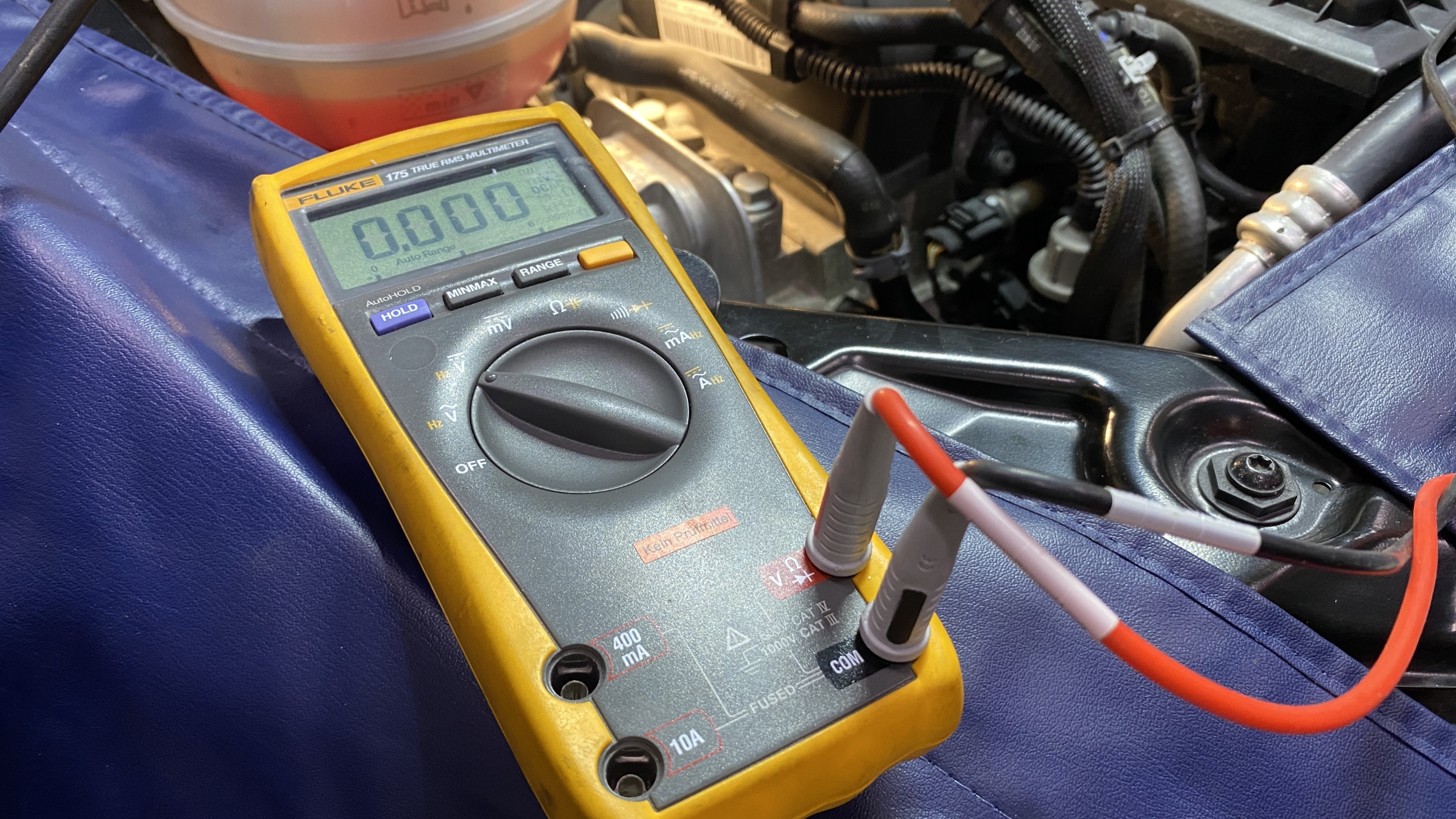

When replacing the BRM in the vehicle, first switch off the engine and wait for any coasting time to elapse. Then disconnect both the 12V and 48V batteries and use a voltmeter to check that there is zero voltage at the BRM contacts.

The communication interface connector may only be disconnected when the machine is de-energized and voltage-free.

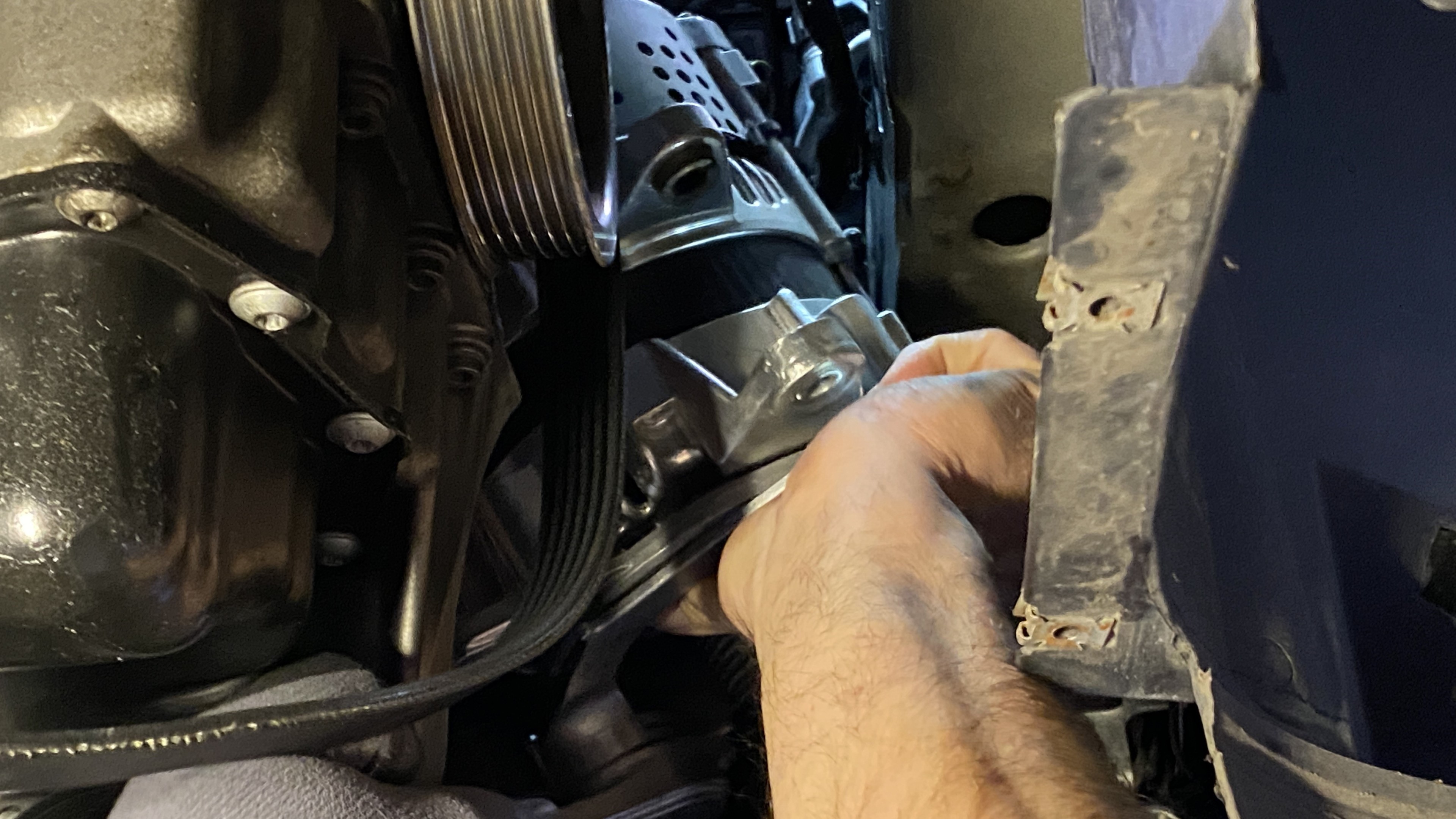

If it is a liquid-cooled BRM – recognizable by the corresponding connections for the cooling water – the cooling water must be drained according to the manufacturer's instructions before the supply line can be disconnected.

Further installation is comparable to that of a generator.

What else needs to be considered?

- The BRM must be stored horizontally (see picture above) and must not be placed on the electronics. This can damage the connectors and electronics and lead to machine failure.

- The rotor shaft must not be subjected to axial loads during handling. This will damage the bearings, which can shorten the service life of the machine.

- Measures must be taken to prevent electrostatic charging and discharging of the BRM and its components, e.g., by wearing ESD protective clothing.

- The 48V electrical system does not feature reverse polarity protection. Reverse polarity, even for a short time, must therefore be avoided. This can lead to undetectable damage or failure of the BRM.

- When restoring the screw connections, refer to the vehicle manufacturer's documentation for the correct torques.

Finally...

- Remember to reconnect both the 12V and 48V batteries.

- Connect the BRM to the diagnostic system and download the latest software version for the device.

Removal and installation at a glance.

Aftermarket Marketing Contact

SEG Automotive

Ullrich E. Schaab

[Opens in a new tab]

ullrich.schaab@seg-automotive.com